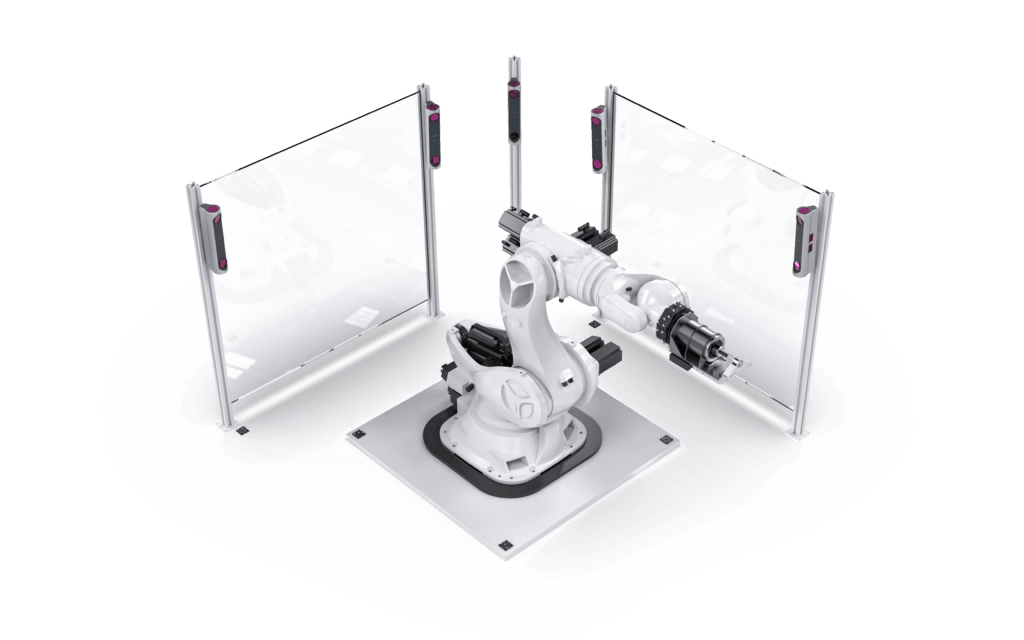

Introducing IONA

Accurate positional awareness for robots

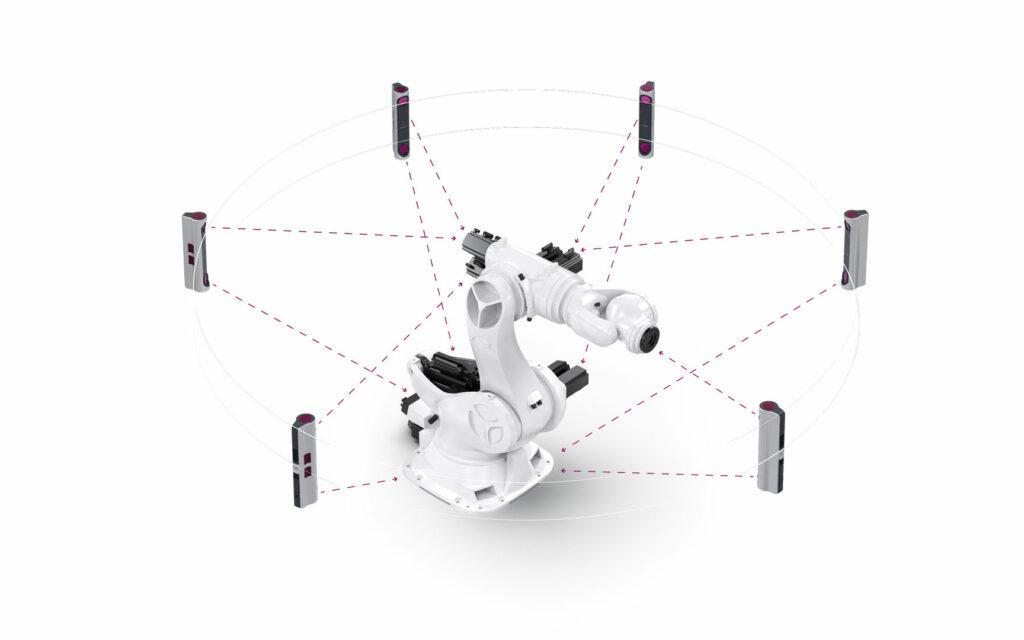

IONA is a scalable network of sensors providing metrology-grade data for industrial robots.

IONA Outcomes

20X

Faster alignment process

Automated Robot to Part Alignment

10X

Increase in process accuracy

Improves robot performance

100%

Confidence through 24/7 monitoring

Continual process monitoring

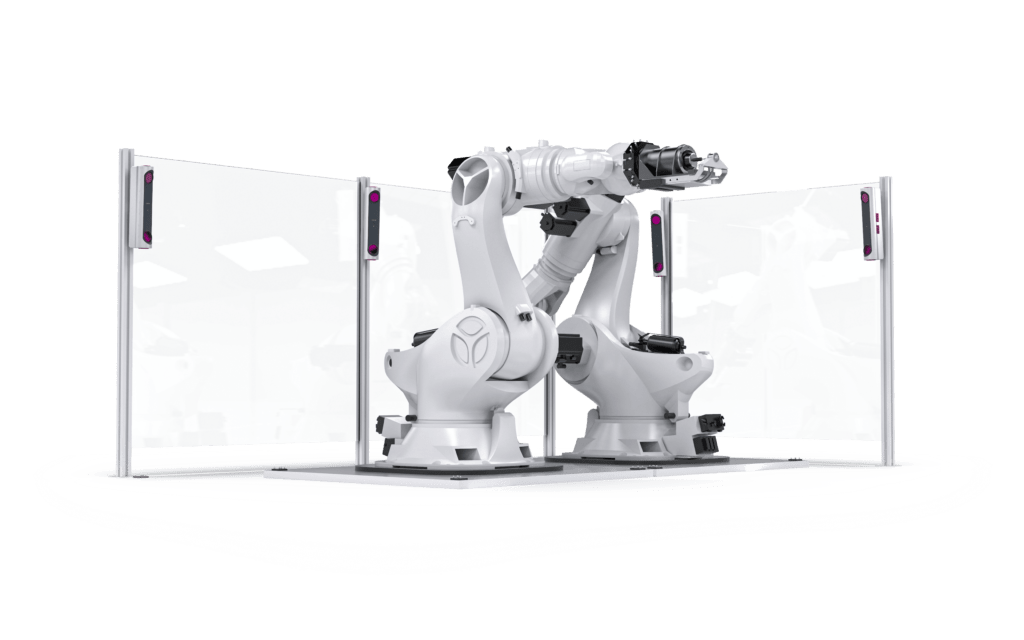

The System

The IONA system is comprised of a network of sensors (nodes) permanently deployed in a manufacturing environment allowing continuous data capture. The system simultaneously captures live data from multiple points of interest – Robots, Fixtures, Datum features etc. The ORA software analyses data and autonomously feeds back updates to the robot, PLC or factory MES.

"Exciting technology!"

IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing for the future.

Andy Silcox, Research Director, AMRC Cymru

Andy Silcox, Research Director, AMRC Cymru

"Innovative system for advance manufacturing!"

We see IONA having an integral role in the future of advanced manufacturing.

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

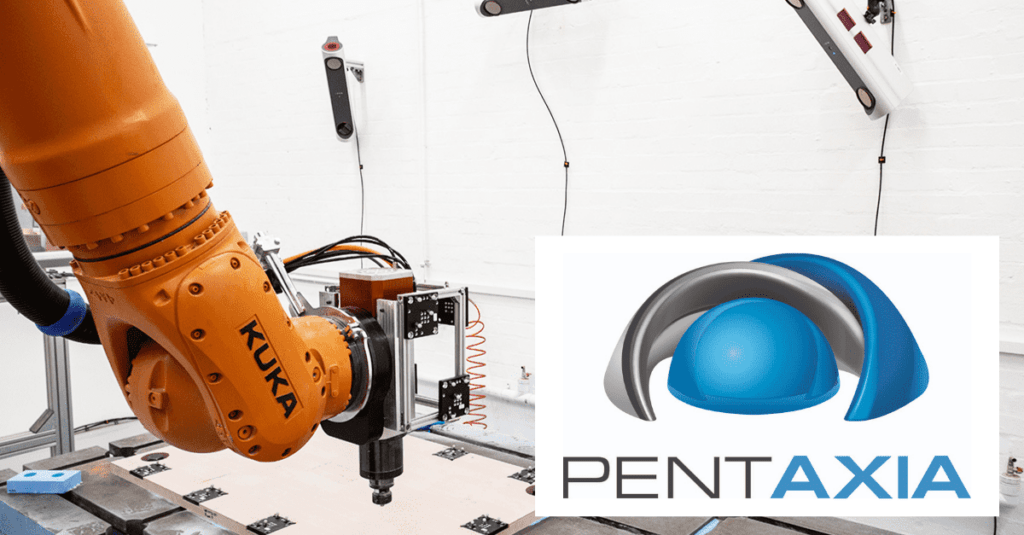

"Achieve process confidence"

As we develop scalable and robust automation solutions in the composites industry, the IONA system shows promise for increasing process confidence and flexibility.

Dr Stuart Morris, Engineering Director, Pentaxia

Dr Stuart Morris, Engineering Director, Pentaxia

Play Video

"Exciting technology!"

IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing for the future

Andy Silcox, Research Director, AMRC Cymru