Predictive Maintenance for Automation

Introduction to Predictive Maintenance

Predictive maintenance is using data and evidence of performance to determine optimum maintenance intervals for individuals assets in the manufacturing system. This is as opposed to preventative maintenance where an asset is simply maintained at set regular intervals irrespective of whether this is beneficial or not. Predictive maintenance can have a big impact on increasing uptime of manufacturing lines.

The Challenge

When a robot fails in production, unplanned downtime can cost over £10,000 per minute in high throughput systems. As mechanical systems, robots are also subject to wear and tear and their positional accurate can ‘drift’ over time. This can result in processes moving outside acceptable tolerance limits and, in some cases, having to scrap a part. Issues such as these can be caused by the robot itself but can also relate to the fixture or part varying in relation to the robot. The later in the process issues are ‘caught’, the higher the cost impact due to the additional value-added. Worst case the product goes to the customer with a fault which can cost millions in the case of product recalls.

The Solution

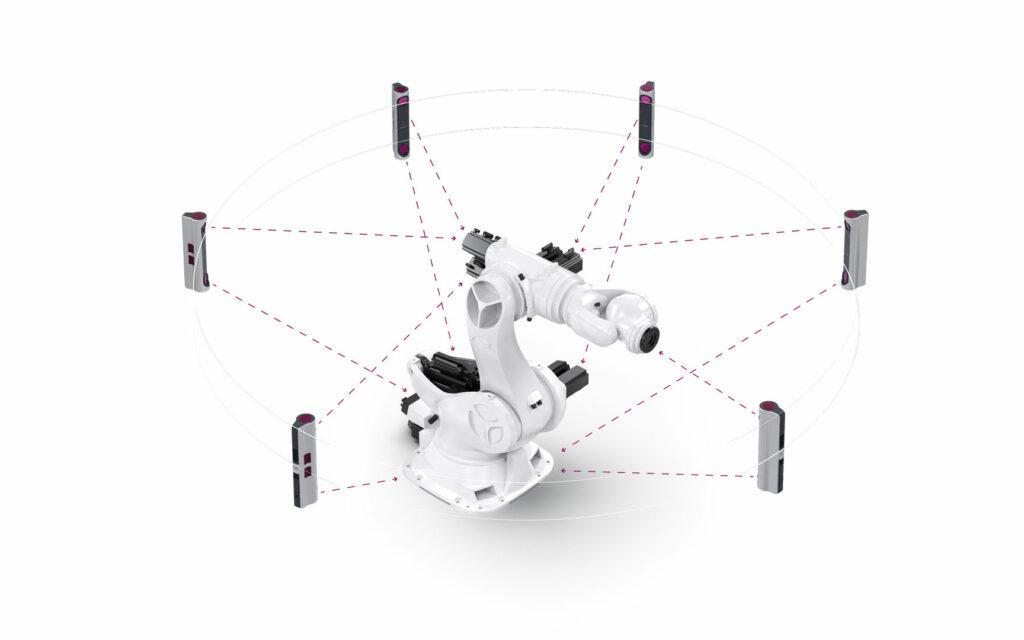

With IONA installed, the position of the robot end-effector or TCP can be monitored in relation to the fixture or workpiece. By continually tracking movements over time, a pattern of behaviour can be established. If the process starts to ‘drift’ either due to a robot issue or the fixture, this will appear as varying from the normal behaviour and flag that an issue may occur. This insight can then be used to predict and then plan when the optimum maintenance intervals will be.

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

"Exciting technology!”

“IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing.”

Andy Silcox, Research Director, AMRC Cymru

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.