Automotive

Introduction to Automotive

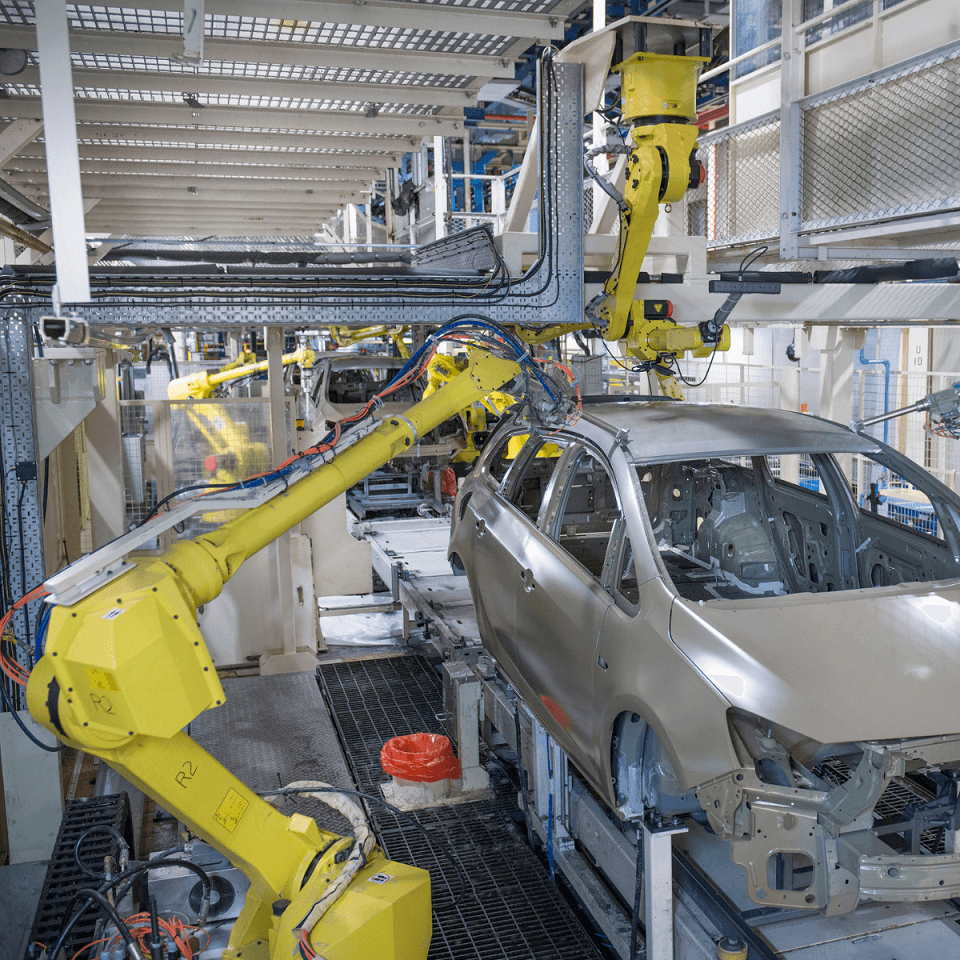

The automotive sector has the highest deployment of industrial robots out of any other industry and have pioneered their use over the past 40 years. Most notably they have been used for welding of body structures and panels but applications have included many other operations such as panel loading, closure fitting, sealant deposition etc

The Challenge

Traditionally, automotive applications have relied on the repeatability of robots rather than their accuracy. This has suited the continuous, high output nature of automotive manufacturing. Characteristically, this has had a very high initial setup cost as the process is ‘tuned’ to perform correctly which is then recouped by amortising costs over years of production. This is no longer sustainable with much shorter new product introduction cycles and a greater level of customisation required by consumers.

When issues do occur in this high output environment the cost of downtime can exceed £10,000 per minute.

The Solution

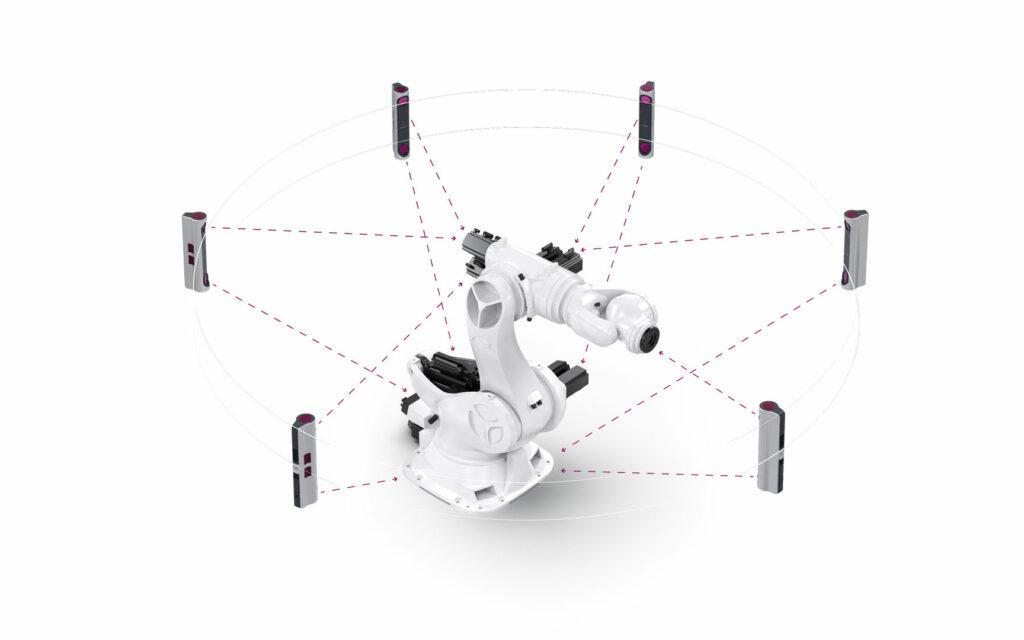

Deploying IONA into automotive production can yield a number of benefits. During initial commissioning, robots can be ‘taught’ using the sensor data rather than an operator having to assess performance through manual checks and producing parts which are subsequently scrapped. This reduces time and cost to commission new robot programs. During production the system can be used to monitor process capability and flag issues early before they manifest as an incorrect part. This can reduce the cost of quality and maintain uptime of production.

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

“Exciting technology!”

IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing.

Andy Silcox, Research Director, AMRC Cymru

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.