Monitoring and control of robot based CNC machining

About Pentaxia

Pentaxia specialises in the manufacturing of advanced composite tooling solutions, prototyping, short-series and volume (typically carbon fibre) component production. Working with both established & emerging composite materials, there is always a key focus on next-generation industrial automation techniques. Pentaxia champions the adoption of these new technologies and continually invests heavily in Research & Development activities.

The Challenge

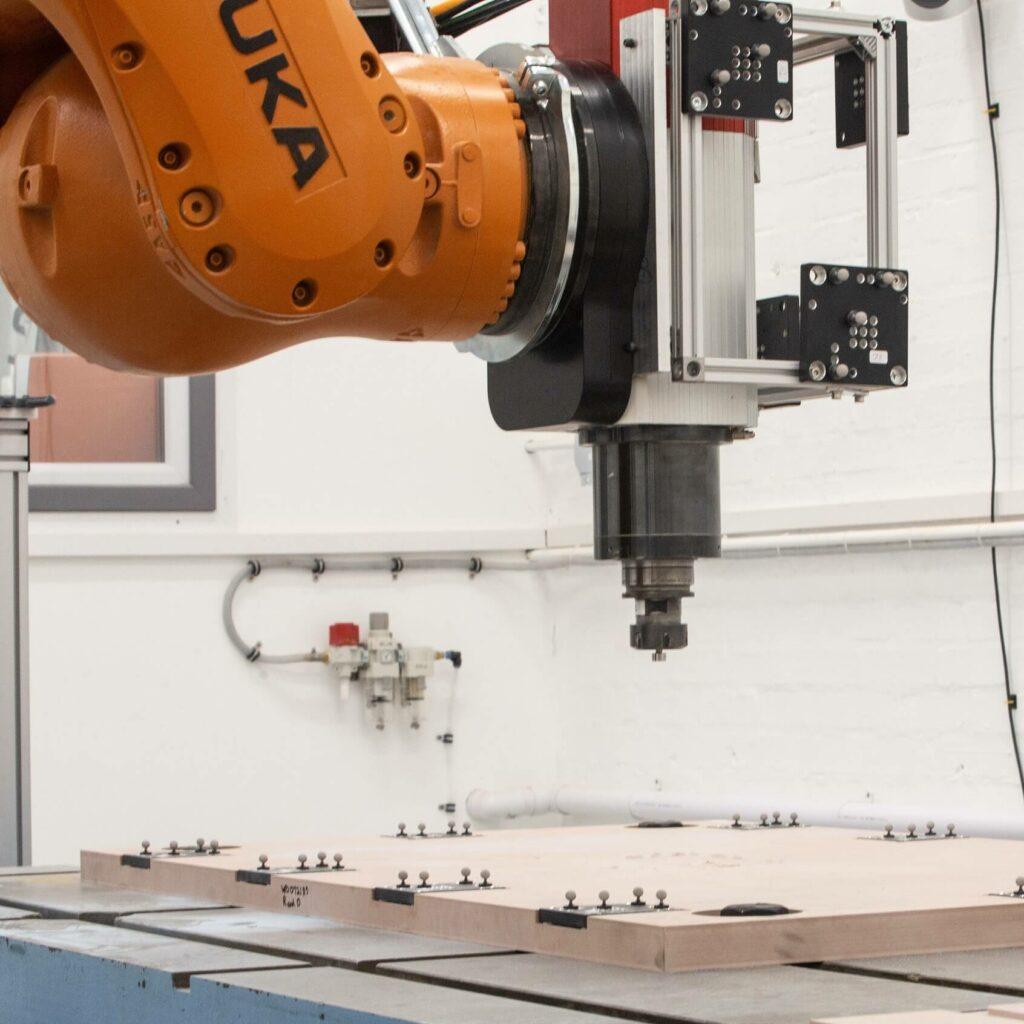

Pentaxia have installed a Kuka robot to perform subtractive CNC machining operations to manufacture composite tooling and foam inserts. The clear end goal is to develop robot CNC machining that is accurate and reliable and can take over relevant operations from more expensive and less flexible 5-axis machine tools.

The Solution

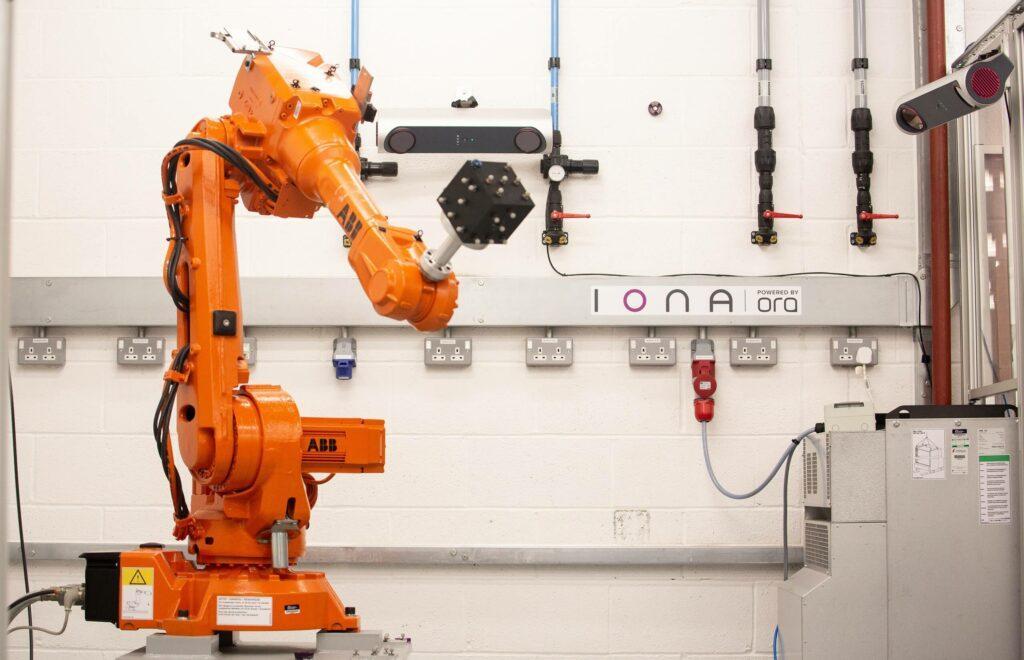

Insphere has extensive experience of using metrology to improve manufacturing processes. We designed IONA from the ground up to deliver accurate, dependable data in complex real-world automation settings.

The Results

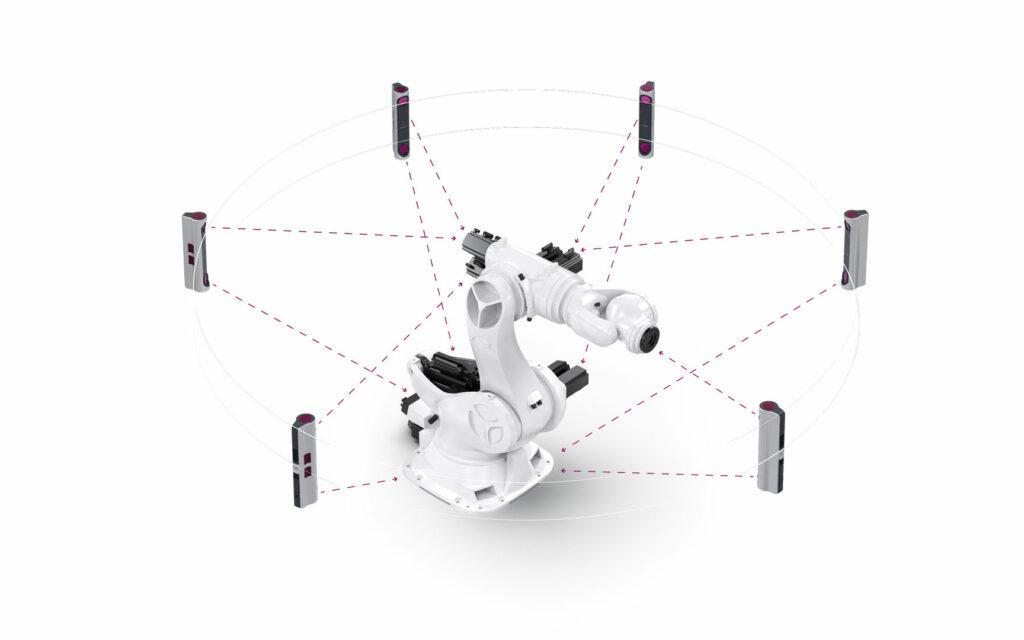

Unlike other metrology solutions, IONA can capture accurate data in a robot cell while manufacturing operations are being performed. It is uniquely robust against environmental instability and uses multiple sensors to avoid line-of-sight restrictions. These features were attractive to Pentaxia who wished to build a deeper understanding of their robot performance when machining tooling block and other materials.

- Installation and use were successful and straightforward

- The presence of the system did not affect other operations in the cell

- IONA tracked the robot with no line-of-sight issues

- The system was able to track continuously 24/7 throughout the volume

- 0.2mm accuracy was achieved throughout the working volume

Accuracy and reliability

IONA has shown potential to improve the accuracy and reliability of robot CNC processes, with a return on investment delivered through faster set-ups, greater robot flexibility, and more accurate parts being produced.

24/7 monitoring

By delivering accurate, real-time, 24/7 monitoring, it is a key enabler of Industry 4.0.

Smart manufacturing

An accurate digital twin of robot operations presents a significant step forward as companies embrace the future of smart manufacturing

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

Innovative Solution

As we develop scalable and robust automation solutions in the composites industry, the IONA system shows promise for increasing process confidence and flexibility’

Dr Stuart Morris, Engineering Director, Pentaxia

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.