IONA Used to Validate Accurate FibreFORM® Performance

About Loop Technology

Founded in 1998 with a growing team of over 50 staff, Loop Technology prides itself in delivering bespoke equipment for customers in aerospace, automotive and renewable energy sectors. Loop’s passion for innovation and forward thinking has given them a strong and expanding portfolio of projects targeted at composite processes.

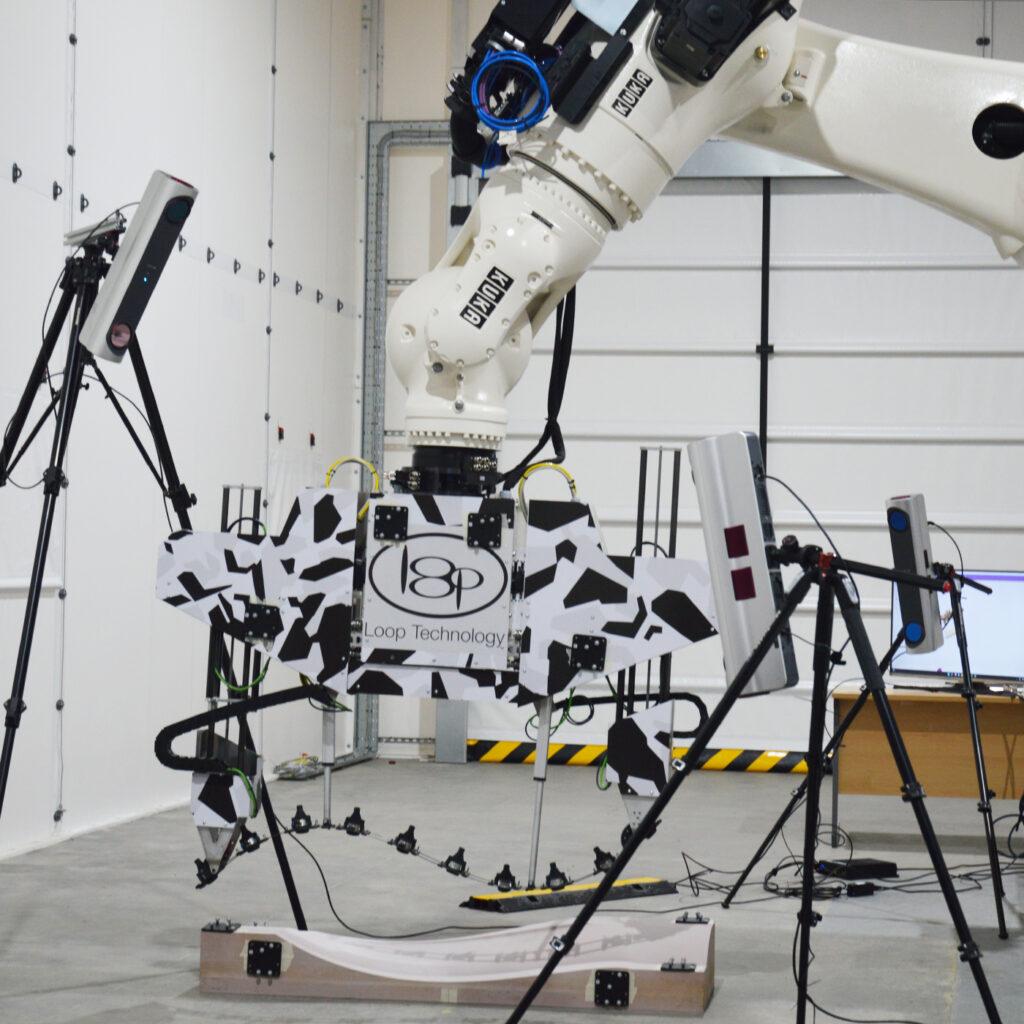

FibreFORM® is Loop’s innovative system, comprising of an array of grippers which are manipulated to generate a double curvature surface perpendicular to the ply surface. Accurate robot performance is critical to success, so IONA is an attractive technology to monitor and enhance the precise position and orientation of FibreFORM® relative to a tool surface.

The Challenge

FibreFORM® can form composite plies into double curvature surfaces making it ideal for laying up fuselage sections, wing skins or engine nacelles.

The Solution

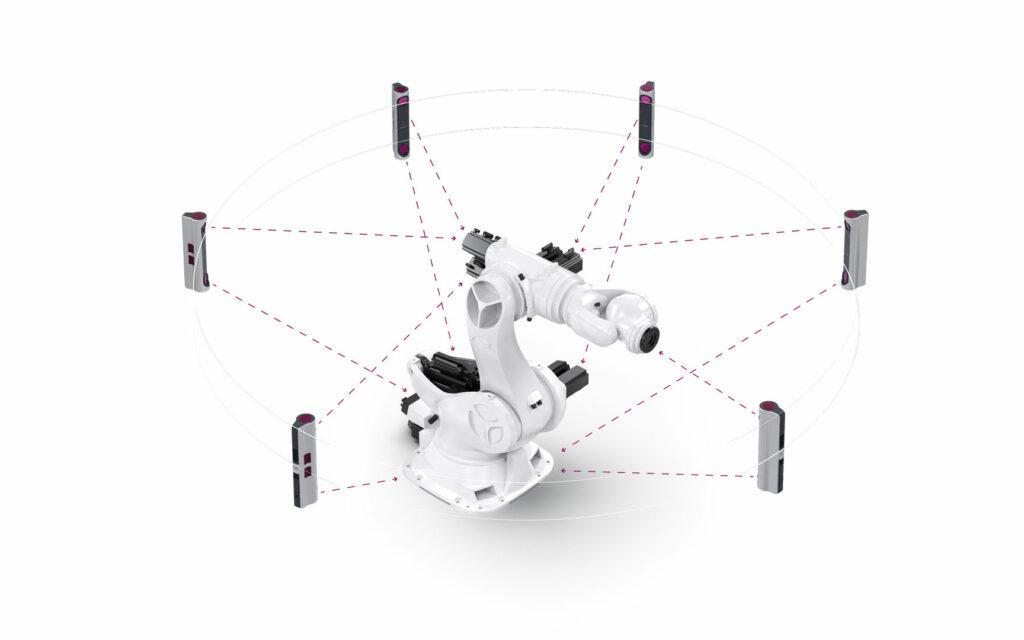

IONA is uniquely capable of delivering high accuracy automation over a scalable working volume and tracking multiple moving bodies simultaneously to generate metrology-grade data in real time. For these reasons, Loop were enthusiastic to trial IONA to validate Accurate FibreFORM® Performance.

The IONA system was set up in Loop’s Advanced Automated Preforming Technology (ADAPT) cell. The cell comprises of a pair of large industrial robots on a linear rail, to create a large and highly flexible working area.

Two robot programs were tracked by IONA, one consisted of the robot moving to multiple fixed points, and the other was a continuous dynamic path. For each program, multiple repeats were performed and datasets were collected from IONA.

The Results

IONA was able to track the FibreFORM® end-effector accurately relative to a tool, in all positions and orientations used in the robot programs.

- Installation was straightforward

- IONA tracked the robot accurately with no line-of-sight limitations

- It was simple to track both the position and orientation of FibreFORM dynamically and statically and make comparisons with desired positions

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

"Attractive system for real-time data!"

As companies adopt FibreFORM for automated material placement, IONA is an attractive system to deliver real-time data to validate and potentially improve process performance.

Alun Reece, Managing Director Loop Technology

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.