Accurate Drilling

Introduction to Accute Drilling

Compared to the large, bespoke cartesian based systems used for automated drill, the industrial robot offers a flexible and versatile deployment mechanism for drilling end effectors particularly for operating over large volumes on structures such as aircraft wings.

The Challenge

Whilst a robot based drilling solution offers many potential advantages over its cartesian based counterpart, its not without challenges. Particularly in aerospace applications, positional tolerances can be tight. This can be hard to achieve with large end-effectors and high dynamic forces acting to on the robot resulting in differences between the programmed drill location and what actually happens. This is exacerbated when large robots are used to counteract forces, combined with 7th axis rails to increase the working envelope, both of which further impact accuracy and consistency.

The Solution

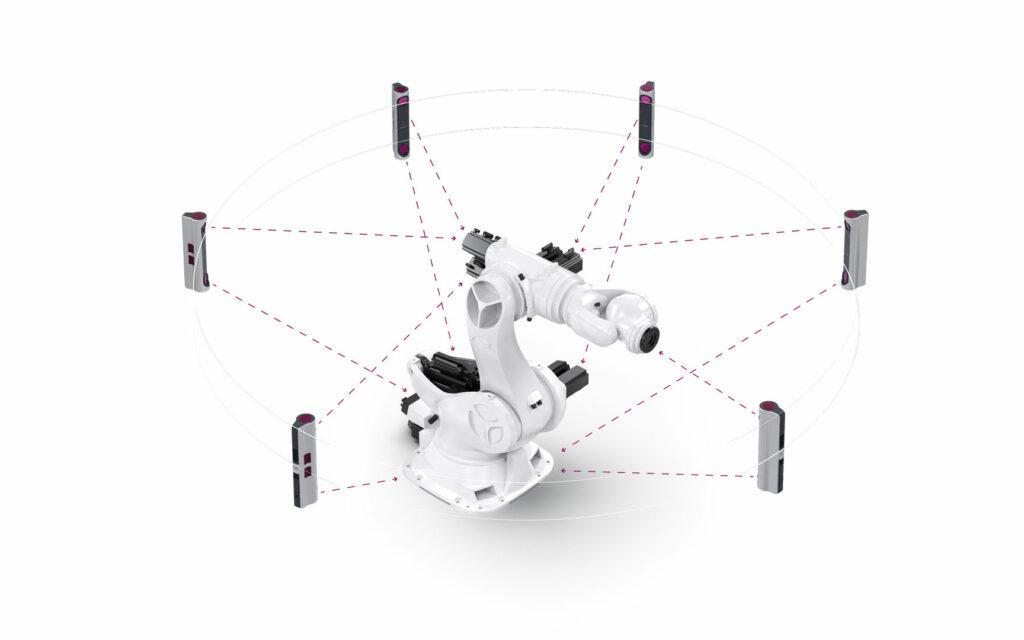

Using IONA a calibration routine can be run to compensate the robot for the high dynamic loads of the drilling end-effector. This can be done across the complete working volume or within local zones.

When the process is running, iterative corrections can be made to the TCP verifying the location that is reached and correcting for differences relative to datum features or the nominal program.

By continually monitoring the process a auditable and traceable dataset can be provided of each of the drill locations.

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

"Exciting technology!"

IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing for the future

Andy Silcox, Research Director, AMRC Cymru

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.