Aerospace

Introduction to Aerospace

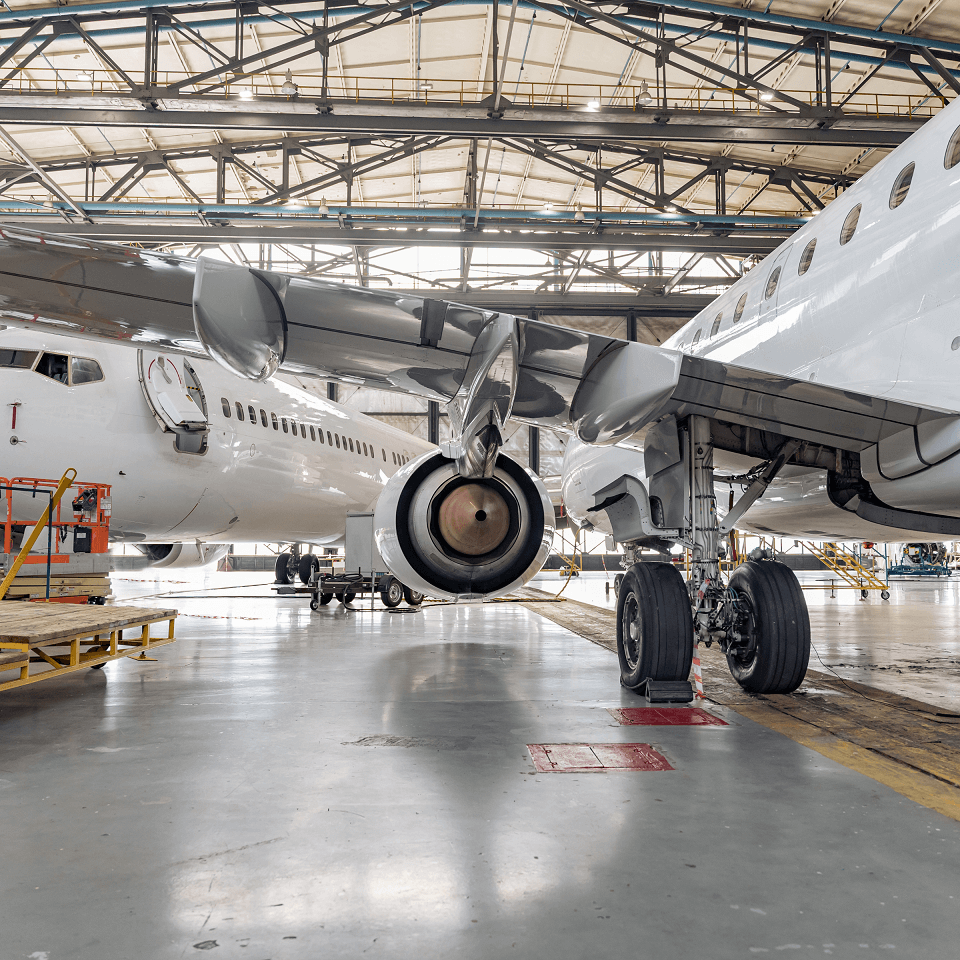

Aerospace manufacturing, especially airframe construction has traditionally been a relatively manual, highly skilled operation using jigs, fixtures and advanced but manual tools. Where automation has been deployed it has typically been bespoke systems designed for specific tasks attracting a very high capital cost.

The Challenge

Increasing volume of production in aerospace is increasingly driving the adoption of more mainstream automation solutions. The product however, is not easy to automate, with large complex structures, very tight manufacturing tolerances and safety critical quality standards to adhere to.

This makes processes such as robot deployed drilling challenging as positional tolerances exceed the capability of a standard robot. This problem is exacerbated by the local positional variation of assemblies.

Assembly using robots presents a similar challenge as alignment is often adapted to conform to local part datum features in order to meet tolerance requirements as opposed to relying purely on fixture positions. Some processes have relied on an element of operator judgement and decision making to determine acceptable fit, a process hard to replicate with automation.

The Solution

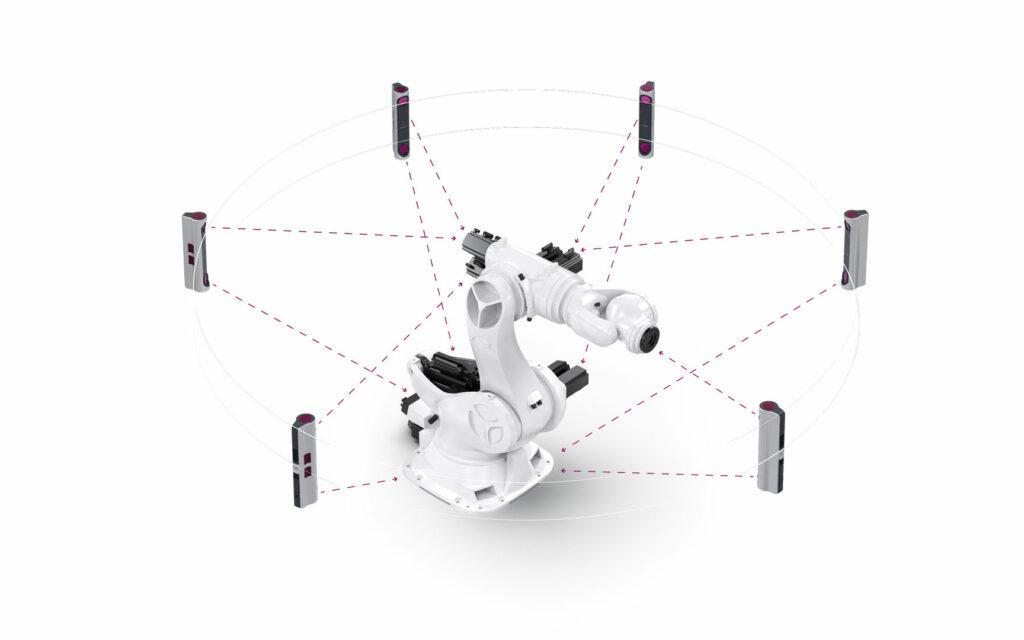

IONA is well suited to overcoming the challenges of deploying robots for aerospace manufacturing. The system can be used to identify critical datum locations of both part and robot TCP, making in-process adjustments to ensure assembly alignment is achieved. Similarly, live adjustments can be made to robot positions relatively part datums during material removal operations such as drilling ensuring correct position tolerances are achieved.

In Aerospace, traceability of manufacturing is a critical aspect of quality and safety standards. Using IONA, robot processes can be autonomously monitored and verified providing critical process oversight.

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

“Exciting technology!”

IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing.

Andy Silcox, Research Director, AMRC Cymru

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.