Rapid, Automated Commissioning

Introduction to Rapid, Automated Commissioning

Before a robot process runs, performing the intent process in production, it has to be commissioned. This involves checking the program is going to perform as intended prior to producing production parts.

The Challenge

Typically, robots rely on their repeatability not their accuracy. When a robot first moves to a programmed position it may only get there to within +/- 2mm. It will however always go back to that same position to within +/-0.05mm. This lack of accuracy therefore often leads to a manual commissioning process taking place. When a program is first brought online, an engineer will use the teach pendant stood next to the robot to manually adjust each of the critical program positions correcting for the inaccuracy. This is clearly a costly and time-consuming process that delays the speed at which new products can be introduced into production. It may also waste multiple parts needed for ‘trial runs’ before the system is corrected. This process is also subjective with the engineer on the shopfloor making decisions about what is acceptable which also creates a challenge when handing over to the process owner.

The Solution

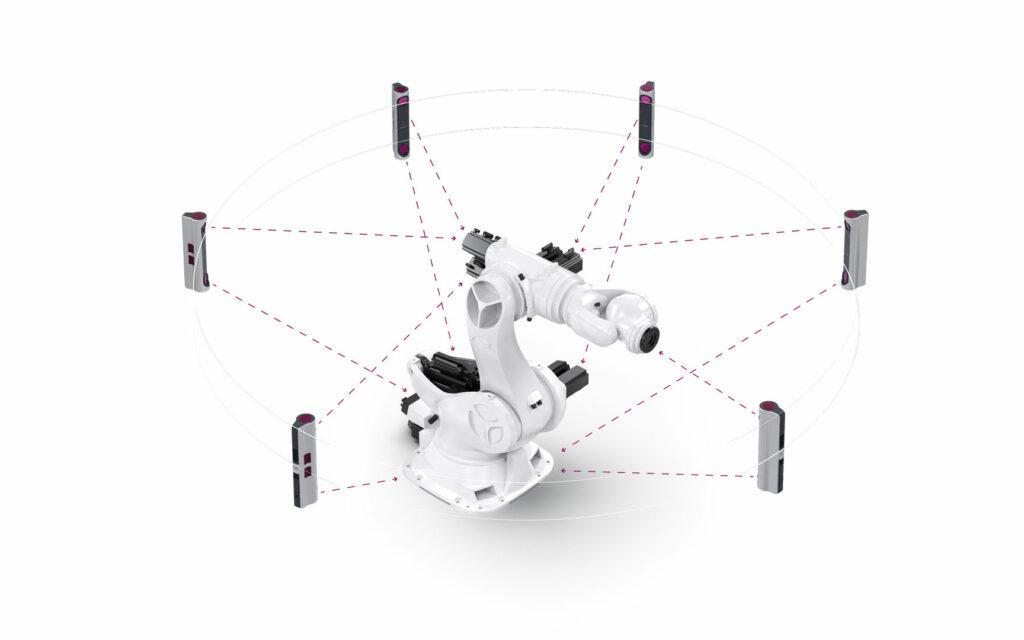

The IONA system allows operators to perform a physical dry run of the program, capturing data using the sensors then using the ORA software to highlight the differences between the intended program and what happens in reality. The changes to correct the program can then be made at the click of a button.

This reduces the commissioning time for introducing a new program change. This is a significant time saving when introducing a new part or model variant. With IONA, program changes or new parts can be introduced more frequently. This also creates a traceable process for program changes and an independent way of validating a robot program.

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

“Exciting technology!”

“IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing. “

Andy Silcox, Research Director, AMRC Cymru

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.