Assembly Operations

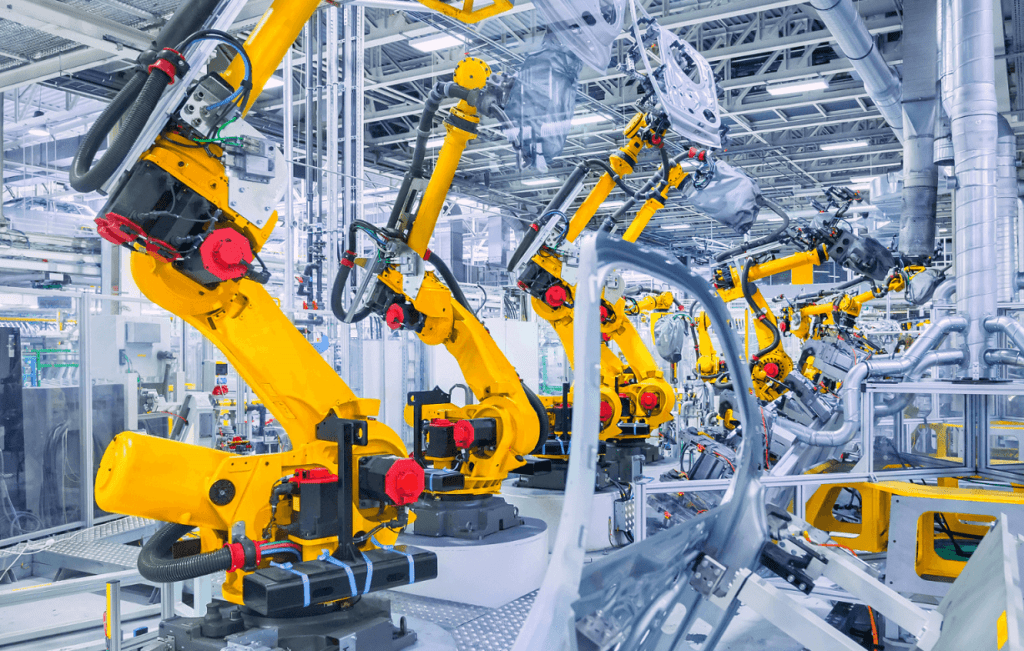

Introduction to Assembly Operations

Increasingly robots are being used for assembly operations, bring parts together while other robots perform material joining operations. One of the advantages in using robots for assembly is their ability to perform tasks on a wide range of product variants of different shapes, sizes and configurations.

The Challenge

Robots lack the positional awareness relative to their environment i.e. they don’t know where they are relative to the part or other robots. This is an important aspect for assembly operations, particularly if the robot is replacing a traditional fixture to align parts.

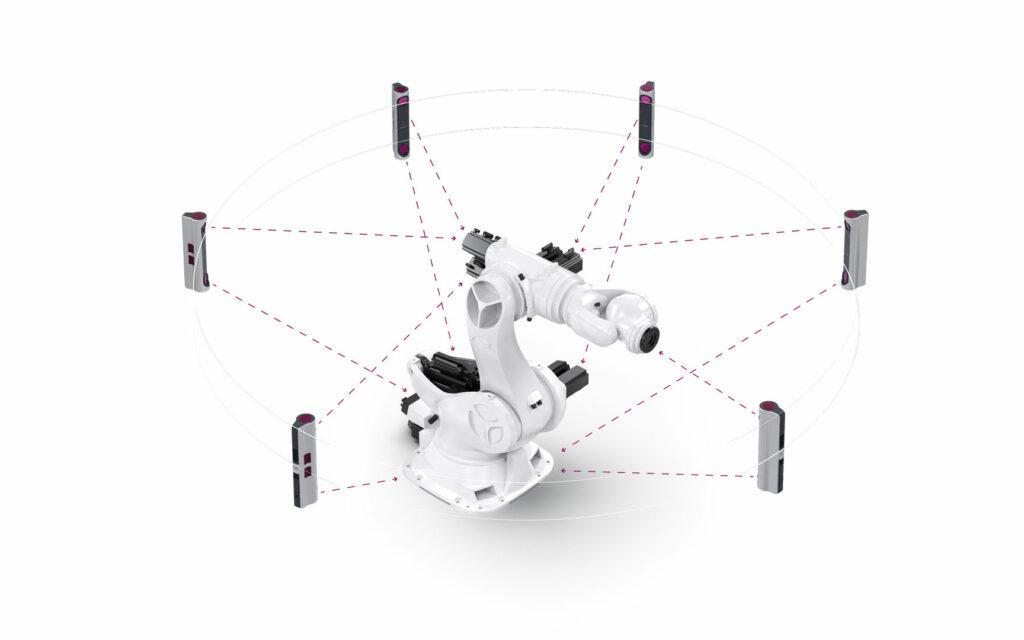

The Solution

IONA can provide the positional awareness for robots performing assembly operations. The robot TCP position can be accurately controlled relative to other robots, parts and datum features using the measurement data generated.

This ensures perfect alignment taking into account physical differences for the nominal simulation or program. This is particularly effective in re-configurable assembly operations.

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

“Exciting technology!”

IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing for the future

Andy Silcox, Research Director, AMRC Cymru

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.