Robot Welding

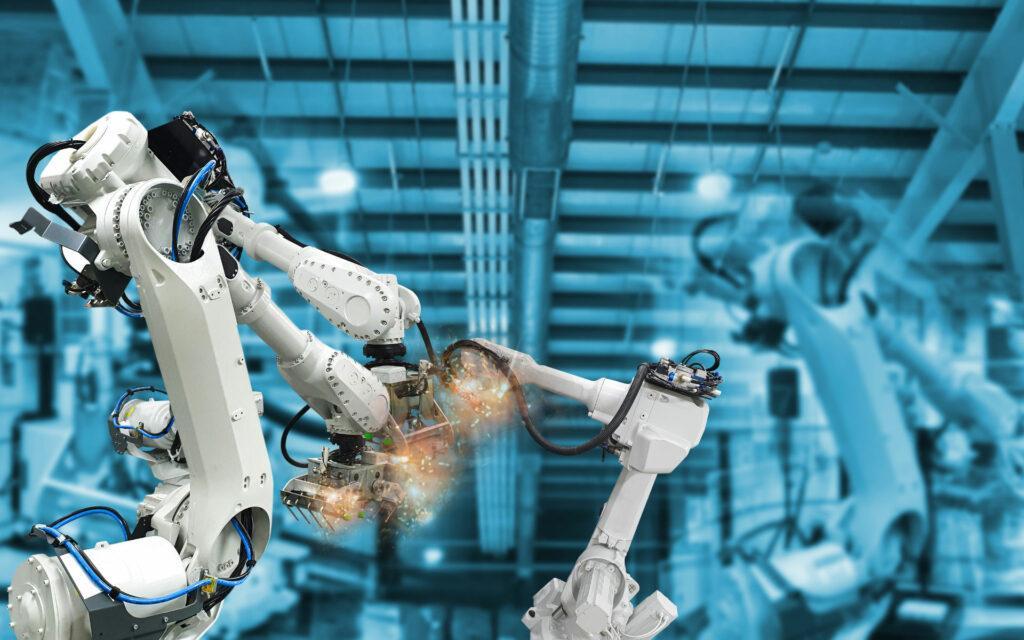

Introduction to Robot Welding

Welding using robots has been one of the mainstays for robot applications since robots were first introduced to manufacturing. Improvements in performance enabled by IONA is now increasing the potential to achieve higher performance welding operations, improving product quality and enabling manual operations to now be automated.

The Challenge

As with any manufacturing process, robots are subject to natural process variation and drift over time. This can be caused by a variety of sources including wear on the robot, variation in environmental conditions and variation in the part. If this process variation is not identified and corrected at source it can impact the part and in worst case lead to scrap or costly re-work.

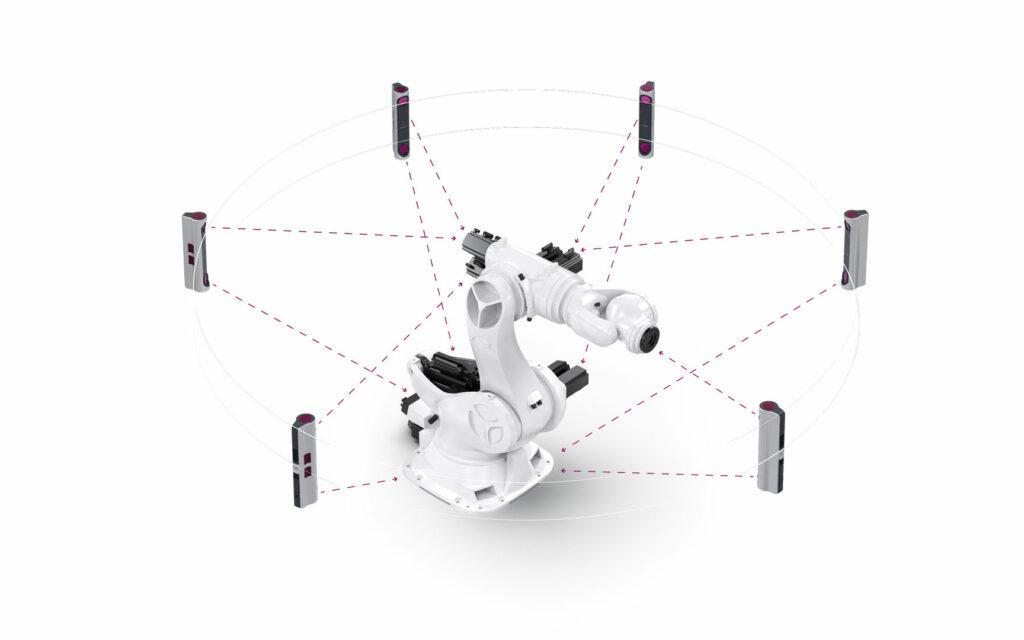

The Solution

Using IONA, the location of the robot TCP can be determined each time a process runs. This can verify that the location of each weld has been performed correctly. If an error is identified, a corrective action can be trigger in-process rather than risking the error manifesting across many parts before being identified.

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

"Exciting technology!"

IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing for the future

Andy Silcox, Research Director, AMRC Cymru

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.