Robot Additive Manufacturing

Introduction to Robot Additive Manufacturing

Additive Manufacturing has revolutionised the way we can produce parts. Until recently these processes have been limited to relatively small volumes and correspondingly small parts. Industrial robots are now being used to deploy polymer and metallic deposition heads, increasing the size of part that can be produced as well as the enabling more complex geometry. This is dramatically increasing the impact and scope of what can be achieved with additive manufacturing processes.

The Challenge

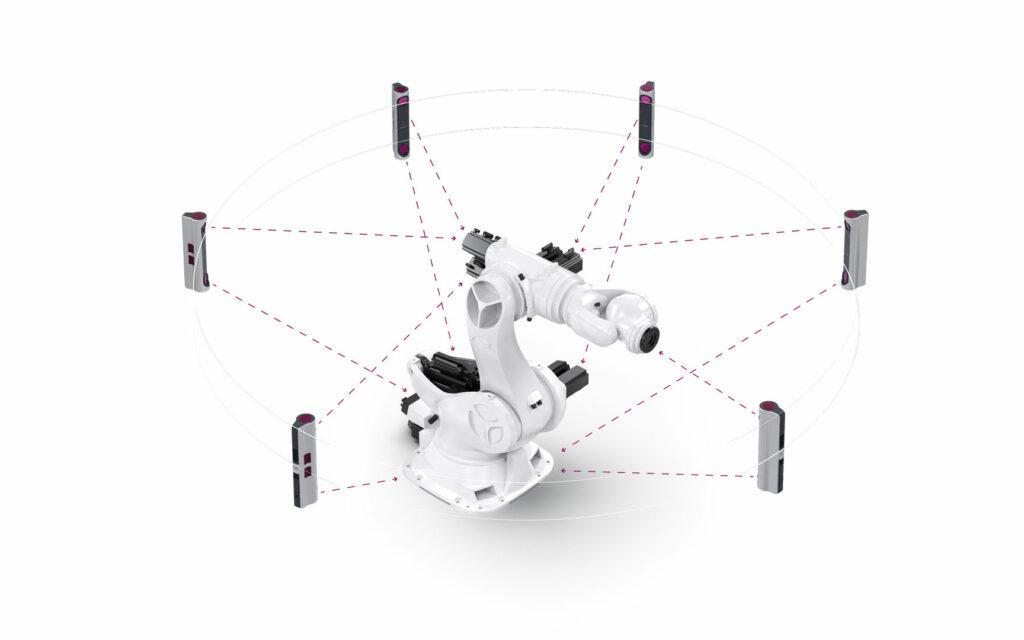

Similar to robot based machining processes, additive manufacturing relies on the accuracy of the robot rather than simply repeatability. This is particularly the case if one off products are being produced which is what additive particularly lends itself to. There are many factors that influence the accuracy of automation such as the position of the joints, end effector loads, dynamic loads, environmental effects, wear and tear on the robot etc. The challenge is that many of these influences vary over time and result in a variation of performance.

Additive build cycle times are often lengthy. If a defect as a result of process variation is not spotted until the process is complete, it can be very costly if the part is scrapped and the process has to be repeated.

The Solution

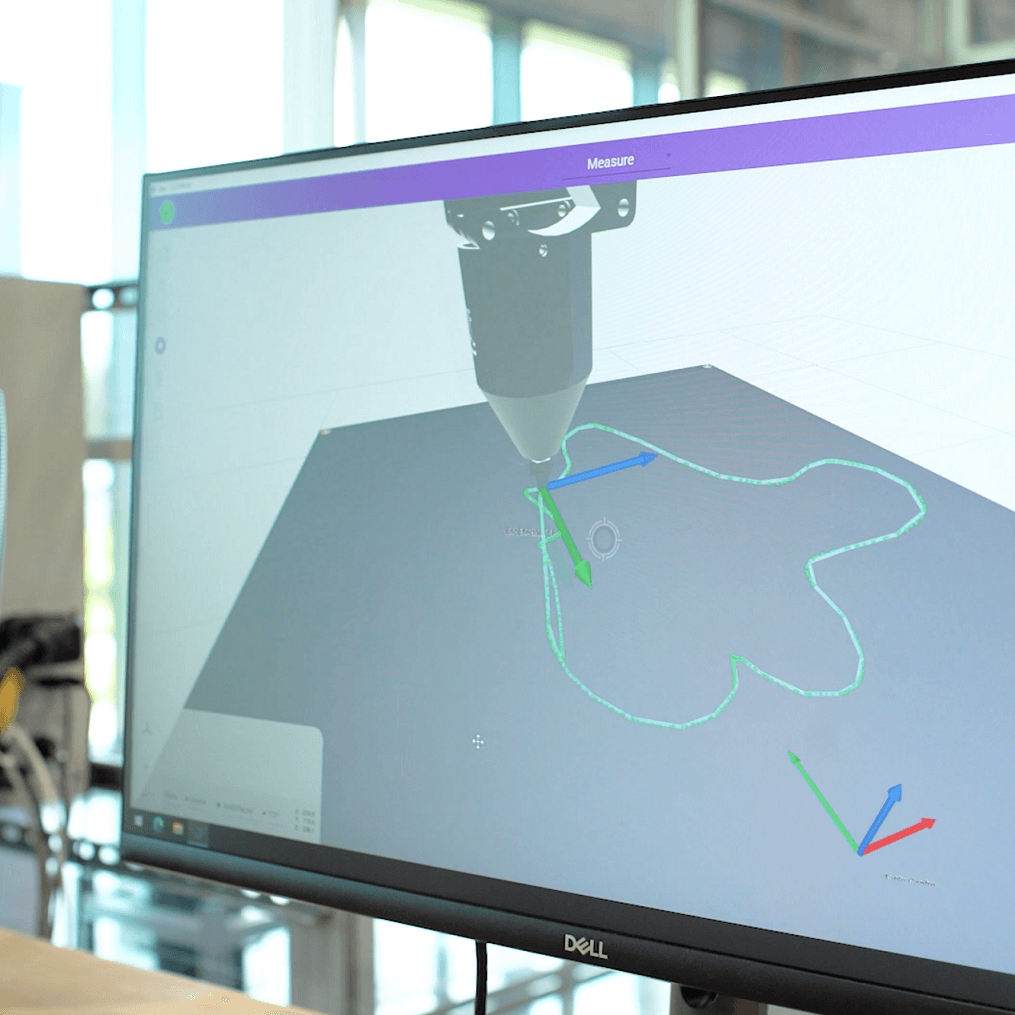

IONA can initially verify the robot set-up and even perform a calibration prior to material being deposited. This ensures the best starting point for the process. During the deposition process, the robot path can be continually monitored providing an immediate flag if the process drifts outside of control limits. If the process does drift, corrections can be made in-process to ensure that part produced is correct.

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

"Real time monitoring!"

We see IONA having an integral role in the future of advanced manufacturing

James Allum, Senior Manufacturing Research Engineer AMRC Cymru

“Exciting technology!”

ONA is a great example of some really exciting new technlogy that is coming to market that will revolutionise the UK Manufacturing for the future.

Andy Silcox, Research Director, AMRC Cymru

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.