ORA software solution applied at Satellite Applications Catapult

INSPHERE awarded contract with Satellite Applications Catapult

Introduction

INSPHERE are delighted to have been awarded a contract with the Satellite Applications Catapult to enhance their robotics yard at the Westcott facility.

The Satellite Applications Catapult is at the heart of the satellite services revolution, driving uptake of space technology and applications to shape, and sustain, the world of tomorrow. Helping organisations bring new services to market, they connect industry and academia, launching new research and bringing knowledge to the market more quickly than might happen otherwise.

One project at Satellite Applications Catapult involving the use of robots in space lacked the level of precise, flexible data analysis that would allow them to accurately replicate and control robot activity. A conversation with INSPHERE about the ORA software platform led to the application of this software to provide this functionality.

About Satellite Applications Catapult

One of nine not-for-profit, independent technology and innovation centres, the Satellite Applications Catapult connects businesses with UK research and academic communities. The Catapult helps organisations make use of, and benefit from satellite technologies, and is continually exploiting the innovation potential in the UK industrial and academic communities.

The Challenge

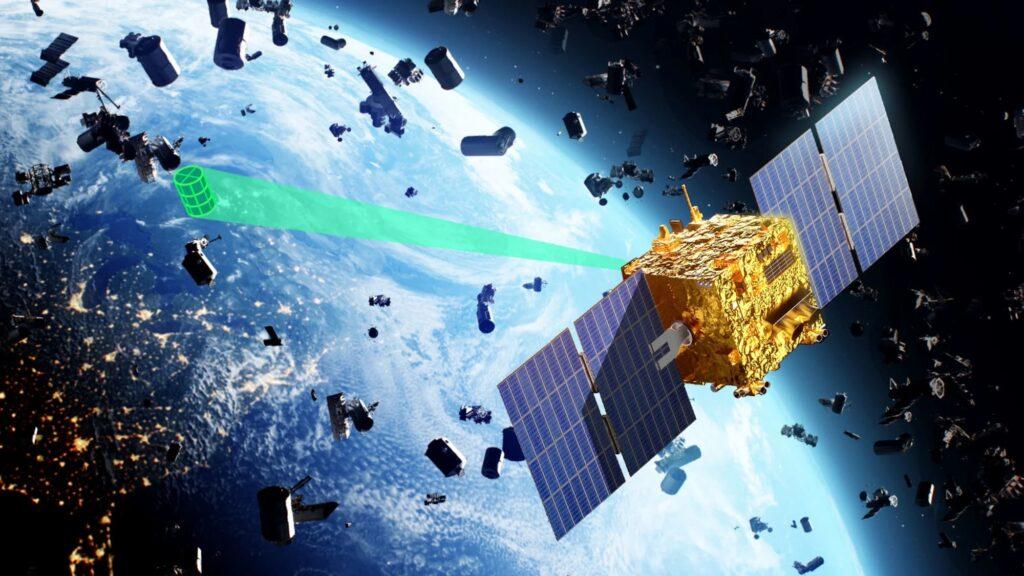

This specific project creates an environment to enable the UK space sector to investigate potential methods to collect space junk, or space debris, identified as any piece of machinery or debris left by humans in space.

There are around 7,500 active satellites orbiting Earth, and 3,000 inactive satellites littering space. In addition to this, there are around 34,000 pieces of space junk bigger than 10 centimetres in size and millions of smaller pieces that could prove catastrophic if they hit something else. So the challenge is finding ways to collect big objects such as dead satellites that have failed or been left in orbit at the end of their mission, spent rocket bodies and smaller pieces of debris , all moving in a variety of speeds and direction.

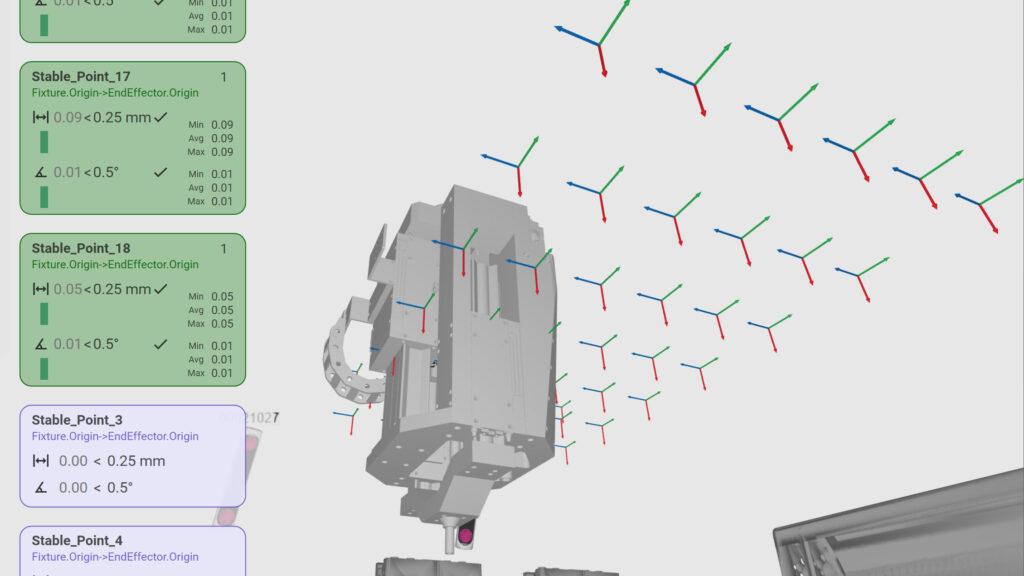

With existing robot tracking hardware in place at their In-Orbit Servicing and Manufacturing Facility, the Catapult already had a level of data and knowledge available to them. However, raw data alone requires interpretation to be useful – of greater value is the ability to create an accurate digital twin of the robot system using this data – ORA software from INSPHERE does just this and provides actionable insights to improve operation.

The Solution

Considering the ultimate aim of being able to accurately track, replicate and control robot activity in space, Satellite Applications Catapult were keen to have software that would work with their existing hardware and provide in-depth data analysis with digital twinning capability.

Following an initial meeting, INSPHERE analysed the Catapult requirements and was able to demonstrate how ORA software could work with their existing system to provide detailed analysis of robot activity, together with any real-time adjustments required without the need for interaction with the robots.

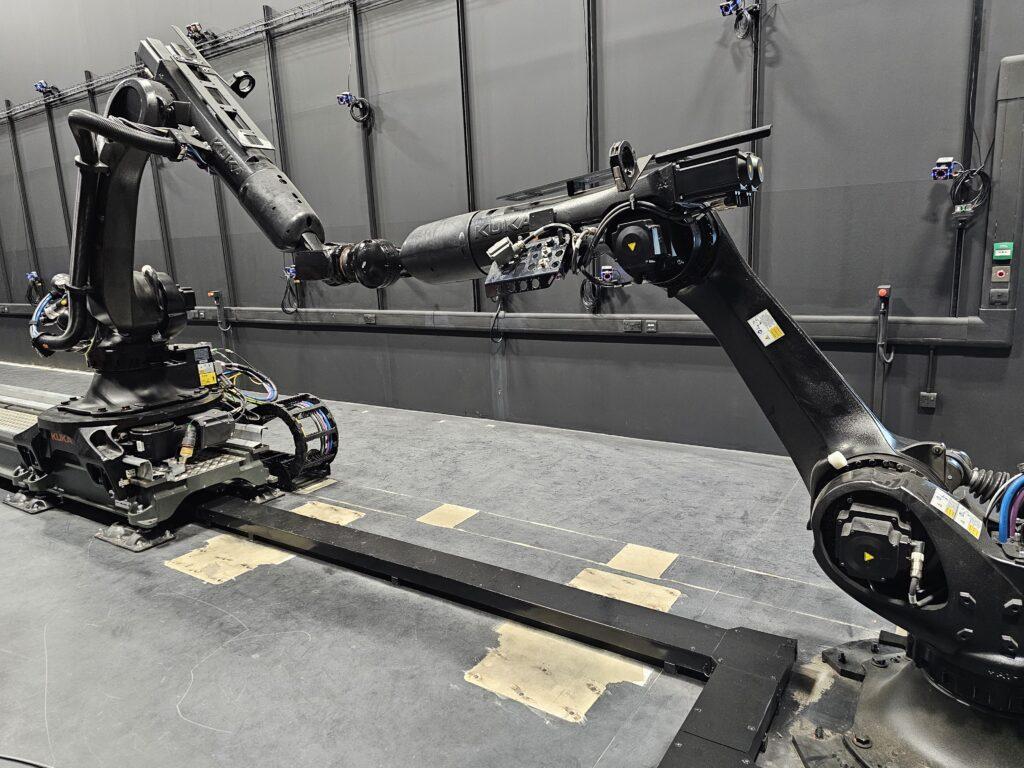

A key part of securing this contract was the ability for ORA to work with a variety of industrial robot platforms and measurement systems. In this case, ORA was adapted to communicate with KUKA robots using a real time control interface, allowing corrected robot positions to be streamed to the robots during operation.

The Results

The ORA software platform provides live positional data that can be used to correct for process variability including part location, robot cell setup or inherent errors in an automated system – making ORA a key tool in enabling flexible solutions.

ORA reduces commissioning time, allowing the user to bring offline programmes online without the need for manual intervention, an obvious requirement for robots that exist in space. Metrology-grade data is used to improve the accuracy and performance of robots, often enabling new processes to be automated.

ORA software analyses data from the sensor network, which can be autonomously fed back in real-time to the robot controller to correct for process variation. This enables ORA to operate as a ‘black-box’ providing data autonomously on demand.

“We are currently upgrading our development facility which allows the testing of advanced in-orbit robotic applications. The system utilises two KUKA robots along with a Vicon motion capture system to collect real time data. We are delighted with the functionality of INSPHERE’s ORA software which we recently purchased. It provides a unique interface between the motion capture data and the robot controller which would otherwise be extremely complicated to facilitate. As a result, ORA allows us to track and dynamically control the motion of the robots using the Vicon sensors. This greatly enhances the capability of the system, facilitating the testing of satellite alignment, capture, servicing and refuelling technologies. Moreover, the support we’ve received from the INSPHERE team both with ORA and more generally with our robots has enabled us to provide additional capabilities to our clients.”

Jeremy Hadall, In-Orbit Serving & Manufacturing Robot Development Lead

ORA Outcomes

Flexible

Works with all major robot brands

Use with a variety of sensing systems

In-process control

Real time correction

Improve accuracy & performance

Valuable insights

Trend analysis

Deep learning

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.