Enhancing the Additive Manufacturing cell at AMRC Cymru

About AMRC Cymru

The University of Sheffield Advanced Manufacturing Research Centre (AMRC) Cymru is a £20m state-of-the-art research centre in North Wales. The team behind AMRC Cymru is a powerful partnership between the Welsh Government, local authorities, growth and enterprise agencies and a world-leading R&D centre in advanced manufacturing. Its goal is to help the region’s manufacturing community access advanced technologies that will drive improvements in productivity, performance and quality.

The Challenge</strong

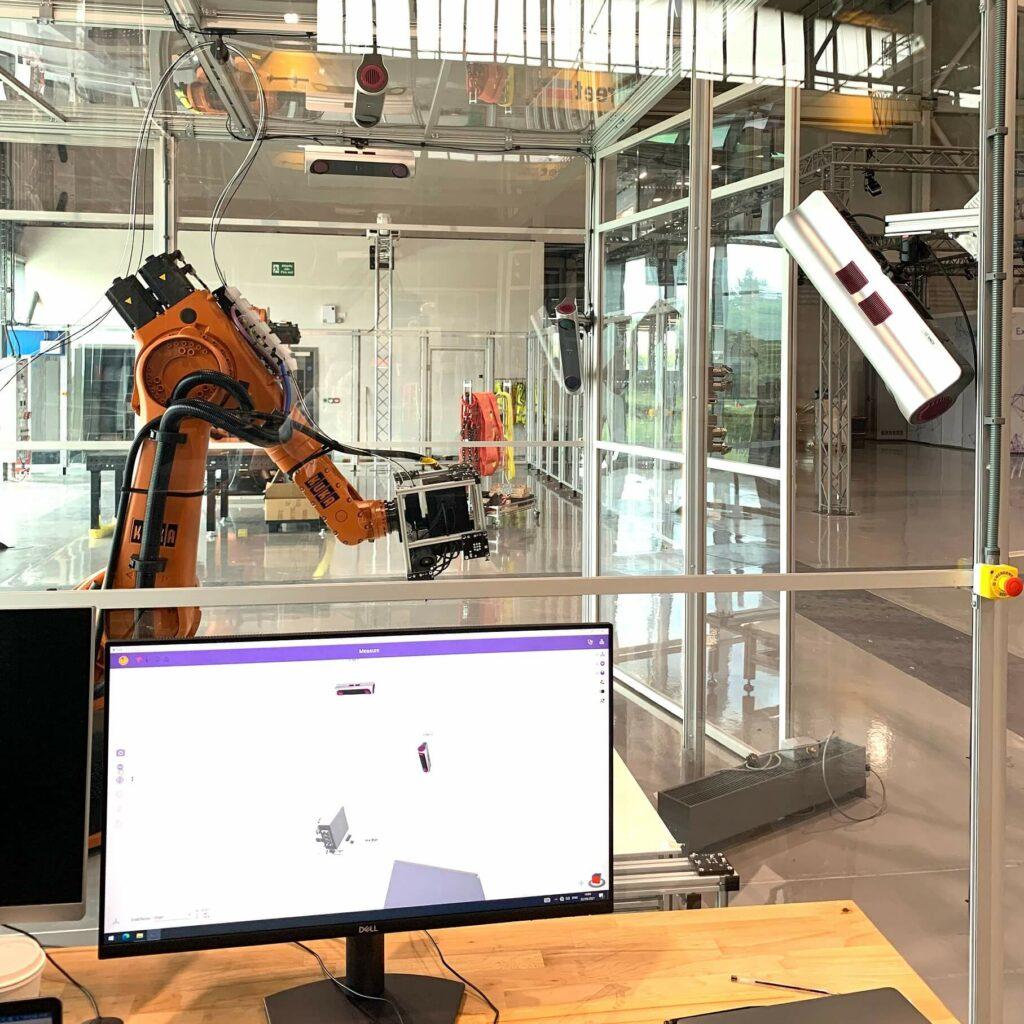

AMRC Cymru is installing a cutting-edge robot cell for additive manufacturing (AM). This new technology has many applications and enables rapid manufacture of large and complex parts which often cannot be made by any other means. For the cell to operate effectively, the robot needs to perform accurately, and its performance needs to be closely monitored at all times.

“We are excited to be installing the new IONA system to monitor our robot AM cell and we look forward to working closely with INSPHERE to get maximum value from the system for the benefit of our members and the wider manufacturing community. We intend to use IONA on a range of robot cells in the centre to demonstrate its value for enhancing automation in aerospace, the food and drink sector, and other applications too.”

AMRC Cymru Research Director, Andy Silcox

The Solution

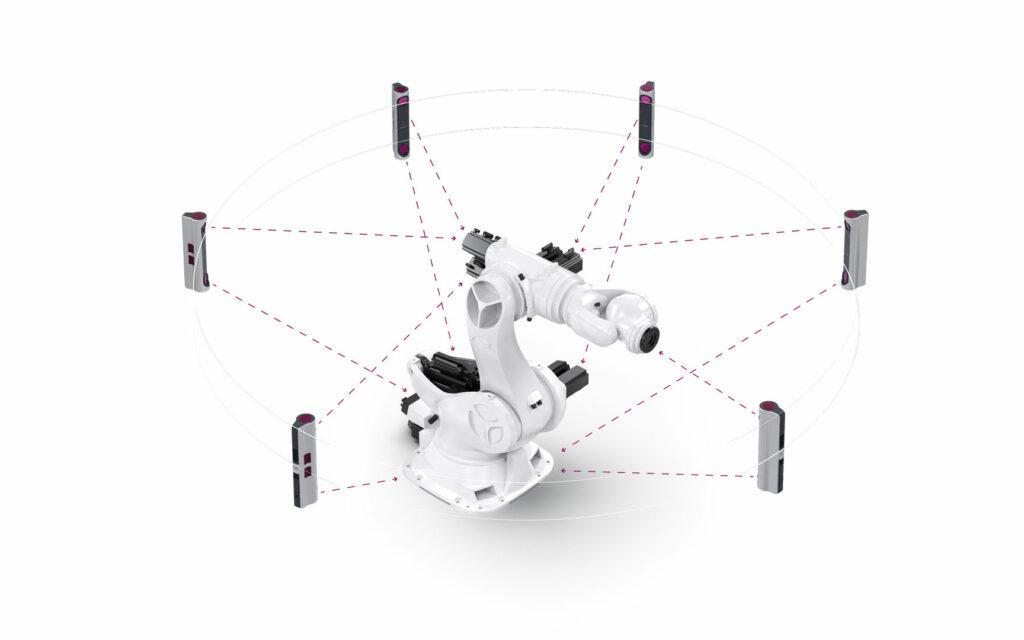

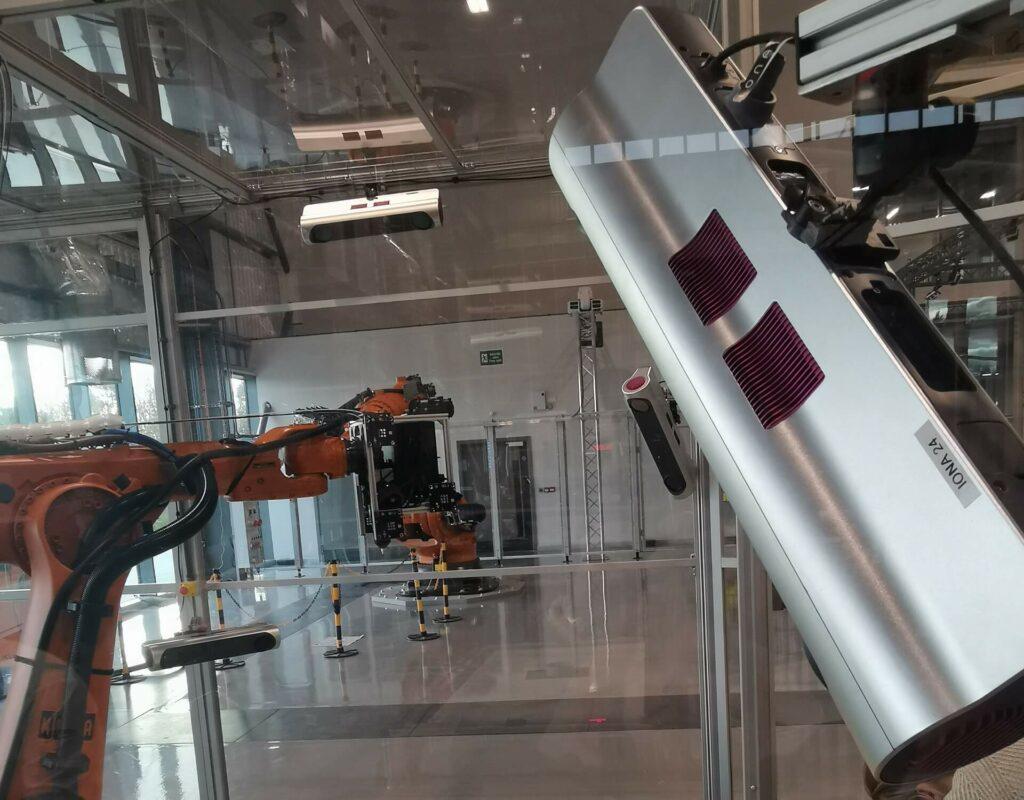

INSPHERE has developed the IONA system to provide accurate real-time monitoring of robotics and so it is ideally suited to this setting. It has the added advantage that monitoring data can be used to control the robot directly through closed-loop feedback, enabling sophisticated control of the robot AM process.

The Results

IONA has provided a method for real-time monitoring of AM builds enabling the identification of process drift as material is being deposited. This has reduced the risk of producing a scrap part and increased process confidence.

Result

Improved System Accuracy – Allowing more processes to be automated and improving process quality.

Result

Correction to robot programs – Enabling faster commissioning and validating a digital twin

Result

Reduced automation downtime – Enabled by predictive maintenance using IONA SPC trend data.

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

"Real time monitoring!"

We see IONA having an integral role in the future of advanced manufacturing

James Allum, Senior Manufacturing Research Engineer AMRC Cymru

“Exciting technology!”

IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing.

Andy Silcox, Research Director, AMRC Cymru

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.