Robot Machining

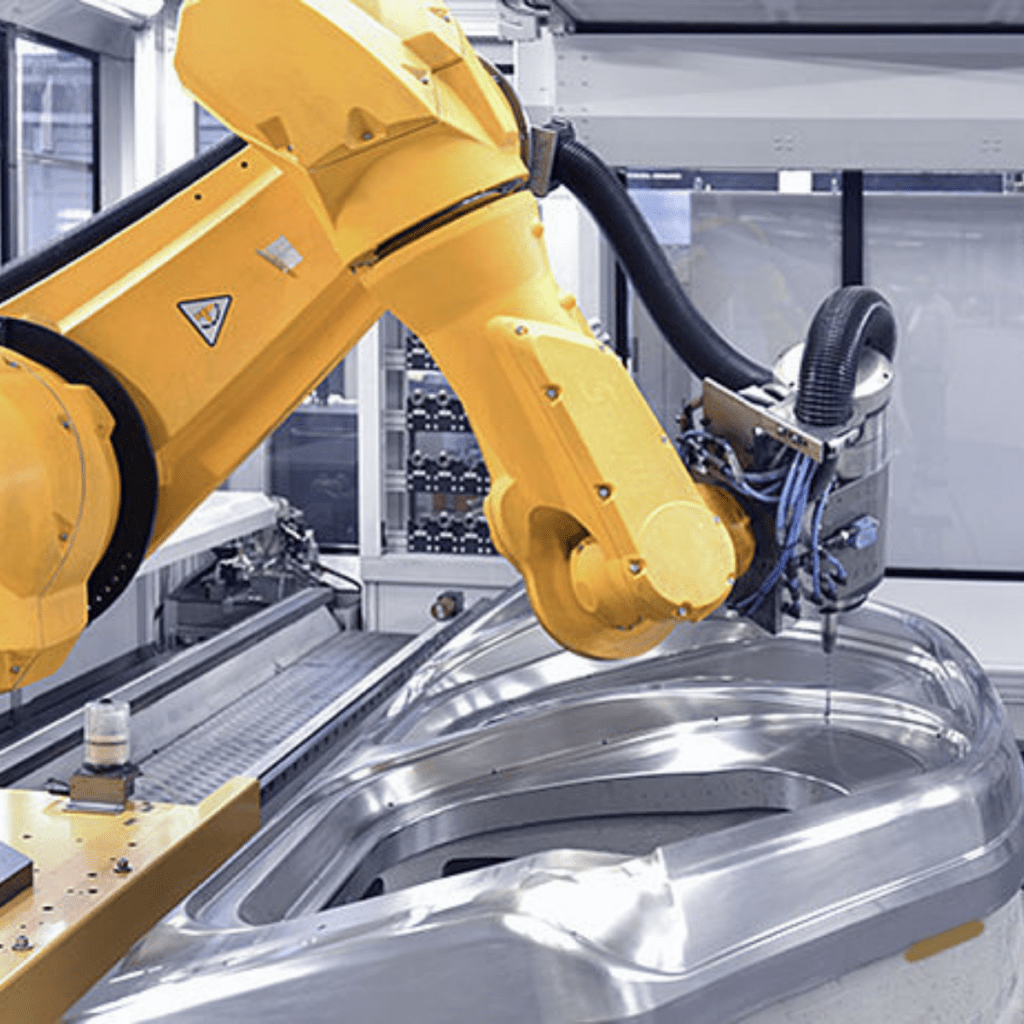

Introduction to Robot Machining

Robots can present a compelling solution for deploying machining processes, offering a lower cost and more flexible and versatile process than conventional CNC machines.

The Challenge

Robots typically rely on their repeatability to perform automated operations but there are some tasks where inherent accuracy is just as important. One example of this is robot machining operations, particularly so if one off products are being produced. There are many factors that influence the accuracy of automation such as the position of the joints, end effector loads, dynamic loads, environmental effects, wear and tear on the robot etc. The challenge is that many of these influences vary over time and result in a variation of performance.

In one example we recently reviewed the customer was having to apply a lengthy, iterative process involving machining, measuring, re-programming, re-machining (sometime several times) to achieve the correct result. This increased the recurring cost of the process threefold consuming both unnecessary machine time and labour.

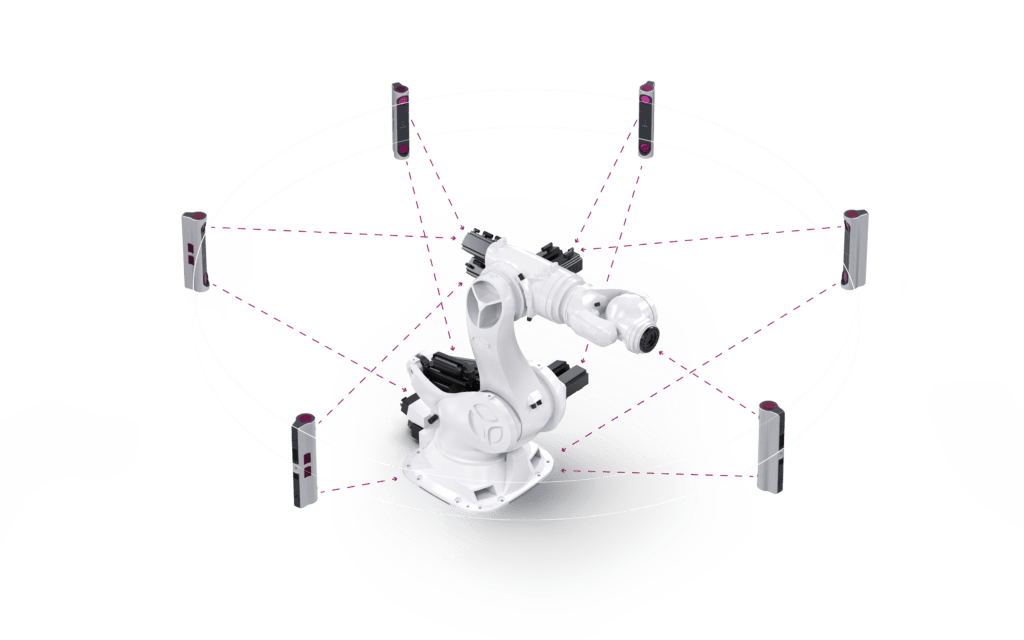

The Solution

In this scenario IONA can be used as a two pronged approach to reduce the cost of production and improve quality. Firstly, a dry run of the operation can be performed prior to cutting material. Capturing data using IONA can be used to validate the performance prior to the critical machining operation. At this stage our Teach module can be used to make corrections to the robot program. Secondly IONA can continue to capture data during machining. This can be used to better quantify the differences between the intention of the program and the end result. When running in Control mode, iterative corrections to the robot program can be made during the process itself further enhancing the performance and efficiency of the process.

IONA Outcomes

20X

faster alignment process

Automated Robot to Part Alignment

10X

increase in process accuracy

Improves robot performance

100%

confidence through 24/7 monitoring

Continual process monitoring

Andy Silcox, Research Director, AMRC Cymru

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru

Dr Stuart Morris, Engineering Director, Pentaxia

“Real time monitoring!”

We see IONA having an integral role in the future of advanced manufacturing.

James Allum, Senior Manufacturing Research Engineer AMRC Cymru

“Exciting technology!”

IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing for the future

Andy Silcox, Research Director, AMRC Cymru

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.