Flexible robot tracking software

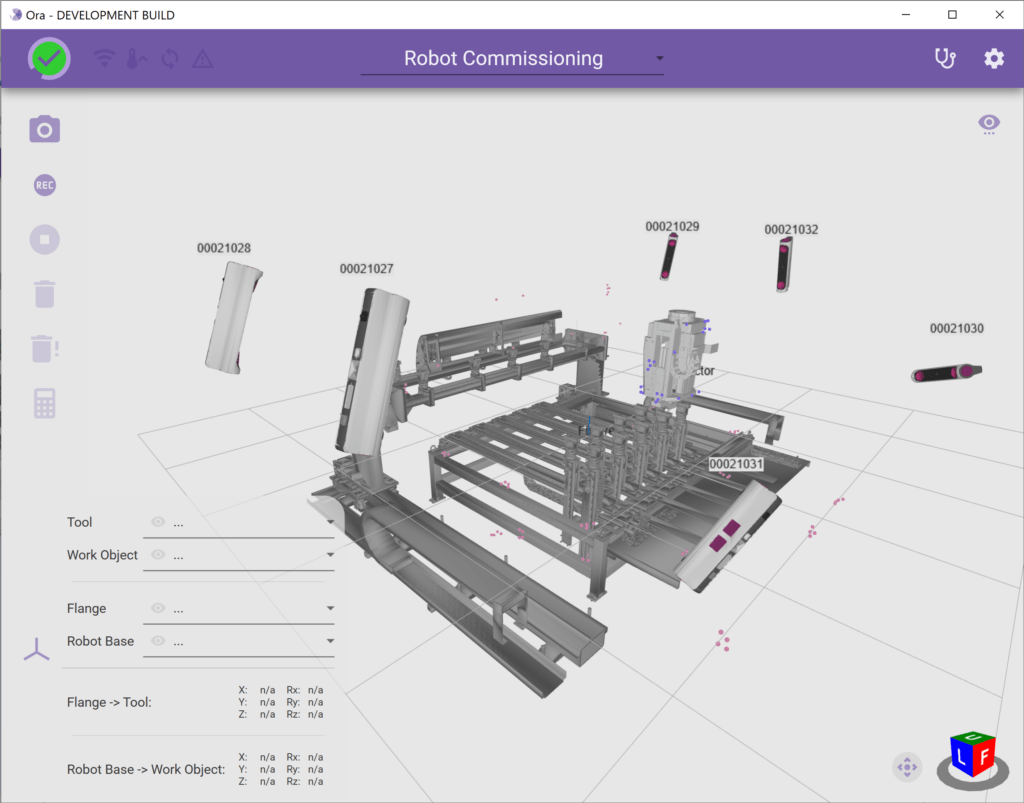

The ORA software platform was originally developed to work with INSPHERE’s IONA hardware – a scalable network of sensors that provide metrology-grade positional data in robot manufacturing cells.

The value of this live positional data is that it can be used to correct for variation in part location, cell setup or inherent errors in an automated system – enabling robot simulations and programs to be updated either periodically or in-process.

However, raw data alone requires interpretation to be useful – of greater value would be the ability to create an accurate digital twin of the manufacturing system using this data. And this is where ORA software from INSPHERE really shines.

ORA can be used with a variety of sensing systems to gain valuable insights, improve process accuracy and performance. The software allows the user to bring offline programmes online without the need for manual intervention, improving efficiency and safety. Metrology-grade data is used to improve the accuracy and performance of robots, often enabling new processes to be automated and further improving the manufacturing process.

Tailored solutions

As each manufacturing process is unique, so too is the software solution provided. ORA works excellently with IONA, its original pairing, yet has the flexibility of being able to work with other metrology hardware or sensor networks.

The ORA software analyses data from the sensor network, which can be autonomously fed back in real-time to the robot controller to correct for process variation. It then integrates seamlessly with the broader smart factory architecture.

ORA can communicate directly with the robot controller or PLC via an API as well as being able to send data directly to the MES platform at the factory level. This enables ORA to operate as a ‘black-box’ providing data autonomously on demand.

Analysing the physical cell set-up, robot movements and fixture alignment, ORA generates results that can then be compared to the program or simulation. Processes can then be updated, correcting for misalignment, inaccuracies and process variation errors.

Find out more about ORA here or request a demo.

July 2024