A live digital twin with real time control.

The essential platform for robot guidance, coordinate frame management and live visualisation.

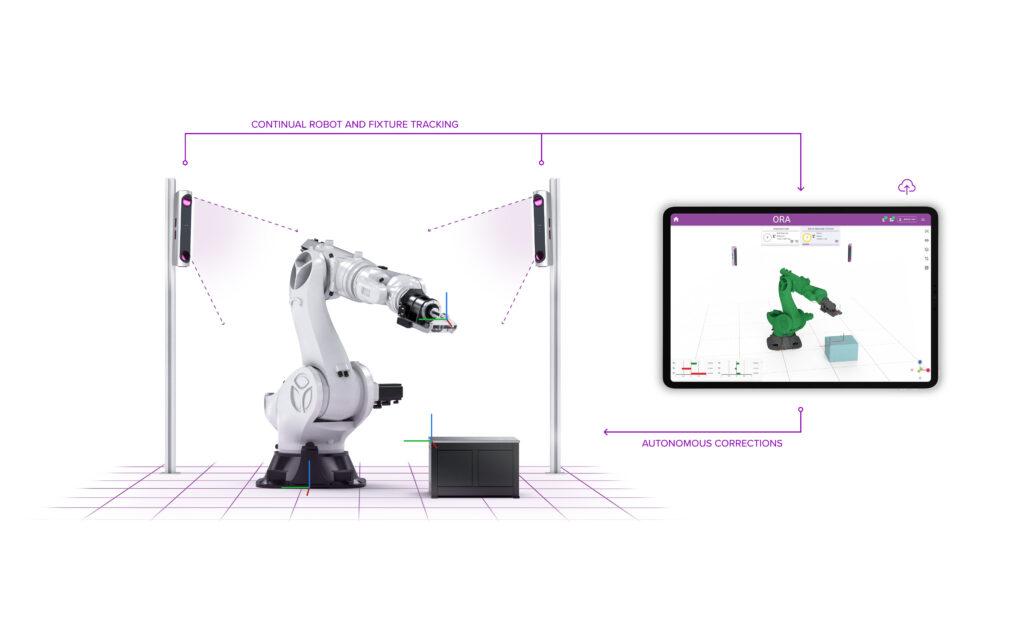

INSPHERE’s release 2.0 of ORA robot control software provides advanced manufacturers with greater opportunities for process improvements and a more intuitive user experience through a live digital twin.

ORA facilitates more accurate and reliable automated processes where manufacturers benefit from fewer quality issues, improved throughput, lower material waste, reduced downtime and greater production efficiencies overall.

Uniquely adaptable in-process control of advanced manufacturing processes

ORA software works with a variety of sensing instruments from IONA, INSPHERE’s original measurement solution, to laser trackers and more. This sensor agnostic feature provides manufacturers with the opportunity to integrate ORA into any existing robot cell set up and benefit from 24/7 monitoring and in-process adjustments, without manual intervention.

Measurement sensors gather all positional data from a robot cell, which is transferred to ORA and compared to the desired activity specification. A digital twin is shown in the user interface to accurately represent activity, allowing users to view frames and their associated CAD models in real time. Deviations in robot activity are identified, with positional revisions fed back to the robots, allowing for corrections to be made in-process, thereby avoiding production errors.

The updated ORA user interface is incredibly intuitive, with users requiring little prior knowledge of metrology systems, and data is clearly presented for easy interpretation of results.

The updated ORA software is available to manufacturers now.