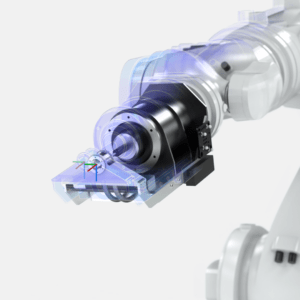

Robot drift in advanced manufacturing processes

In advanced manufacturing, maintaining precision in automated processes is key.

Robot drift, a gradual deviation from the intended robot path, is often inevitable, particularly in high volume, repeated process production situations.

So how can robot drift be avoided?

Production engineers will have KPIs relating to quality, throughput, and other efficiency metrics. When robot drift occurs resulting in potential poor product quality, production downtime and wasted materials, hitting KPIs may not be possible.

While robot drift may not be avoidable for a number of reasons, action can be taken to minimise the extent to which processes are likely to be affected. And you can continually monitor robot activity with ORATM robot control software, creating a digital twin and correcting the drift in-processes to diminish impact on production.

Reducing robot drift is possible. To explore this topic further, download our article ‘Five hidden causes of robot drift (and how to avoid them)’ here.