INSPHERE supports aerostructure manufacture

INSPHERE metrology solutions support aerostructure manufacture

Introduction

In the highly regulated aerospace industry, precision manufacturing accuracy is critical. INSPHERE is working with key aerostrucure manufacturers who are dedicated to continuously improving their manufacturing to meet stringent regulations and the safety of their products.

Collaborating with one such manufacturer, INSPHERE led a key project to test, evidence and deploy significant improvements to the in-process accuracy of precision robots used to manufacture aerostructures. The goal was to achieve ‘right first time’ production, thereby reducing wastage and downtime resulting from automation cell reconfiguration and robot re-calibration.

The outcome of this project was a step change improvement in the production of large aerostructures for the world’s premier aircraft. Our partner is currently applying these innovations to deliver the highest quality aerostructure products.

Find out more about INSPHERE’s solutions

The opportunity

As air travel demand has increased, there has also been an increase in the need for short haul aircraft – in a competitive market, manufacturers must respond to this need quickly. This has required aerospace companies to increase production, ensuring the maintenance of safety standards, without scaling up existing manufacturing facilities. Following the pandemic there has also been a focus to ensure capital expenditure is spent on equipment that can cope with high production demands, while not being dedicated to single products.

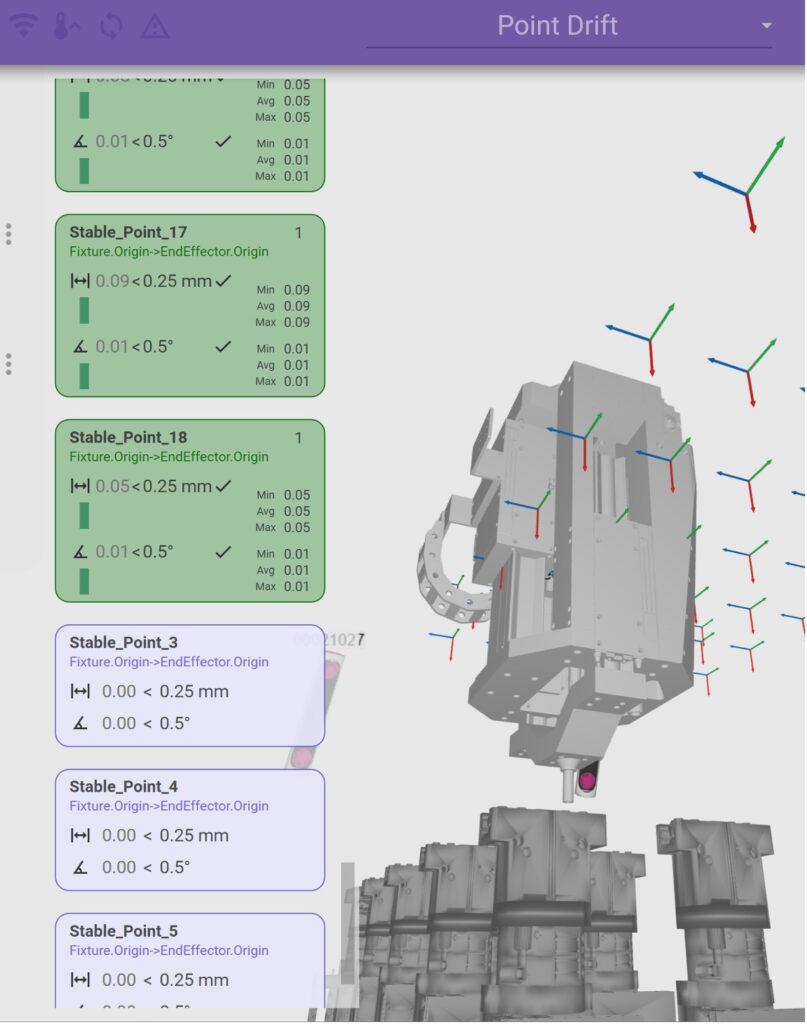

INSPHERE’s IONA technology, along with ORA robot control software, was integrated as part of an innovative project exploring our partner’s new assembly technologies, aimed at delivering improved quality and production adaptability. The critical metrology data provided by IONA enables manufacturers to track, measure, and correct multiple processes across a large working volume, resulting in ‘right first time production’.

Unlike other systems, a key feature is IONA/ORA’s ability to integrate with, and provide accurate positional data, to a wide range of robotic platforms such as KUKA, Universal Robots and Siemens amongst others.

The Solution

INSPHERE investigated ways to help the manufacturer meet their requirements by enhancing their industrial robot capability.

We achieved this by integrating INSPHERE’s unique IONA hardware combined with our ORA software to track, measure and correct activity in their advanced robot cell. Initially deployed in a robotic drilling fastening cell, IONA would be used as a flexible metrology solution within this cell.

The implementation of IONA and ORA delivered the precision and flexibility required to enable a step change in the manufacturing process providing an accurate robot position measurement with a positional tolerance of ±0.2mm.

The technology

IONA’s network of sensors provides the performance required for aerospace manufacturing, offering 6 Degrees of Freedom (DoF), ensuring constant monitoring of the cell and process hardware. The multi-sensor systems also provide transparency to the process by ensuring that targets can be seen from all angles, eliminating total loss of sight when system hardware obscures cameras and targets.

The IONA system is controlled by ORA, INSPHERE’s purpose-built software for robot guidance. This software can track and measure the high-accuracy frame data collected by the IONA system and calculate the correct process outputs. ORA can then communicate and control all cell automation hardware using dedicated Application Programming Interfaces (APIs) or via OPC UA communications. The data recorded by ORA will be sent to an open-source reference framework that establishes the digital blueprints necessary for a state-of-the-art, connected manufacturing facility, allowing for all data to be uploaded and synced to the digital thread.

ORA Outcomes

Flexible

Works with all major robot brands

Use with a variety of sensing systems

In-process control

Real time correction

Improve accuracy & performance

Valuable insights

Trend analysis

Deep learning

“Exciting technology!”IONA is a great example of some really exciting new technology that is coming to market that will revolutionise the UK Manufacturing.

Andy Silcox, Research Director, AMRC Cymru“Innovative system for advance manufacturing!”We see IONA having an integral role in the future of advanced manufacturing.

James Allum, Senior Manufacturing Research Engineer, AMRC Cymru“Achieve process confidence”As we develop scalable and robust automation solutions in the composites industry, the IONA system shows promise for increasing process confidence and flexibility.

Dr Stuart Morris, Engineering Director, Pentaxia

Revolutionising Robot Performance

Unlocking the true potential of industrial robots.