ORA Robot Control Software

A live digital twin with real time control

ORA is the essential platform for robot guidance.

Controlling automated cell activity in advanced manufacturing is easy with ORA. It’s a comprehensive solution that allows you to monitor and improve activity across multiple, varied datums.

Multi-instrument compatibility

Whatever sensors, robots or reference points you’re working with, ORA can track and feedback detailed control information from multiple instruments in-process, optimising production activity. This instrument agnostic feature makes ORA particularly adaptable to different cell set ups.

Complete process visibility

Access full information and control over key datums, past and present, all in one place. This holistic view enables you to better understand what impacts operational success of your automated cell activity, and implement process improvements.

User friendly platform

ORA enables you to have better, more flexible robot performance than ever before, using a platform designed for multiple users, giving each user their individual control over the robot cell in-process – without the need for manual intervention.

Always on

Created to be robust, ORA is capable of operating 24/7 without the need for constant user attention.

What is ORA?

A live digital twin with real time control

Flexible pairing

with existing assets

Use with all sensors, robots , fixtures & datums

In-process control

for real time correction

Improves accuracy & performance

Manufacturing insights

for in-depth analysis

Informs & improves processes

The

ORA Software Platform

Inside information

An intuitive interface has been developed for speedy onboarding and ease of use.

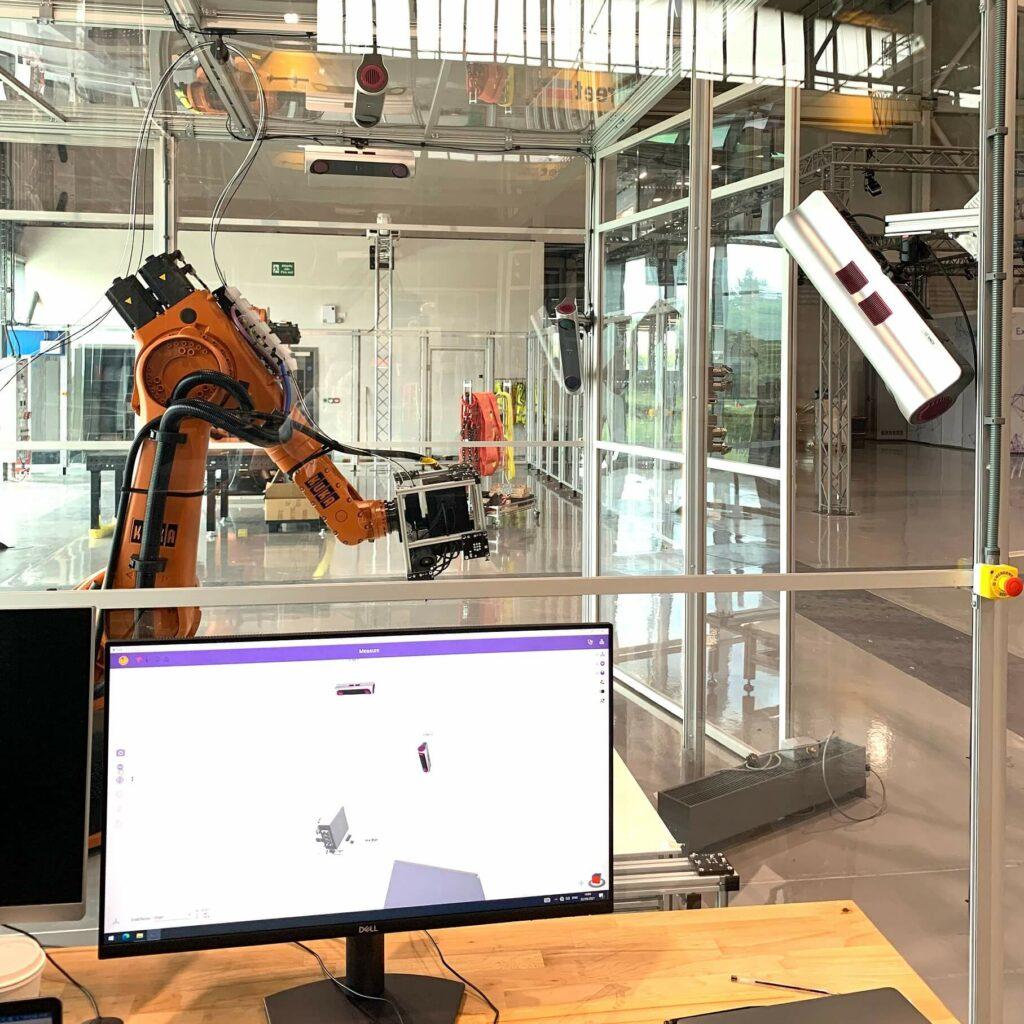

ORA tracks automation activity and fixture alignment from various key datums inside the cell, generating in-depth data that can easily be compared with the program or simulation.

Robot processes can be instantly updated without manual intervention, correcting for misalignment, inaccuracies and process variation errors.

ORA Software Features

- Flexible – use with laser trackers and sensors. ORA can also integrate with other software systems for a completely tailored solution

- Efficient installation and commissioning

- Ease of integration with major robot OEMs, communicating in native programming language such as KUKA KRL, ABB Rapid and Fanuc KAREL

- Library of standard functions accessed via an API, including: - Verification of Robot Path, - Tool and Base Calibration, - Automated Fixture Alignment - Iterative TCP Correction

- Ability to operate as an autonomous ‘black-box’, fully integrated with the robot controller or cell PLC, providing data when requested by the robot program

- Intuitive user interface with 3D environment and graphical display of the data generated.

- Support for OPC-UA and MQTT communication protocols allowing seamless integration with MES platforms at the factory level

- Ability to send data to advanced digital manufacturing applications such as digital twin or input to detailed SPC analysis.

Robot Sensing Systems Data Flow

ORA robot control software: connecting seamlessly with automated cells and factory systems

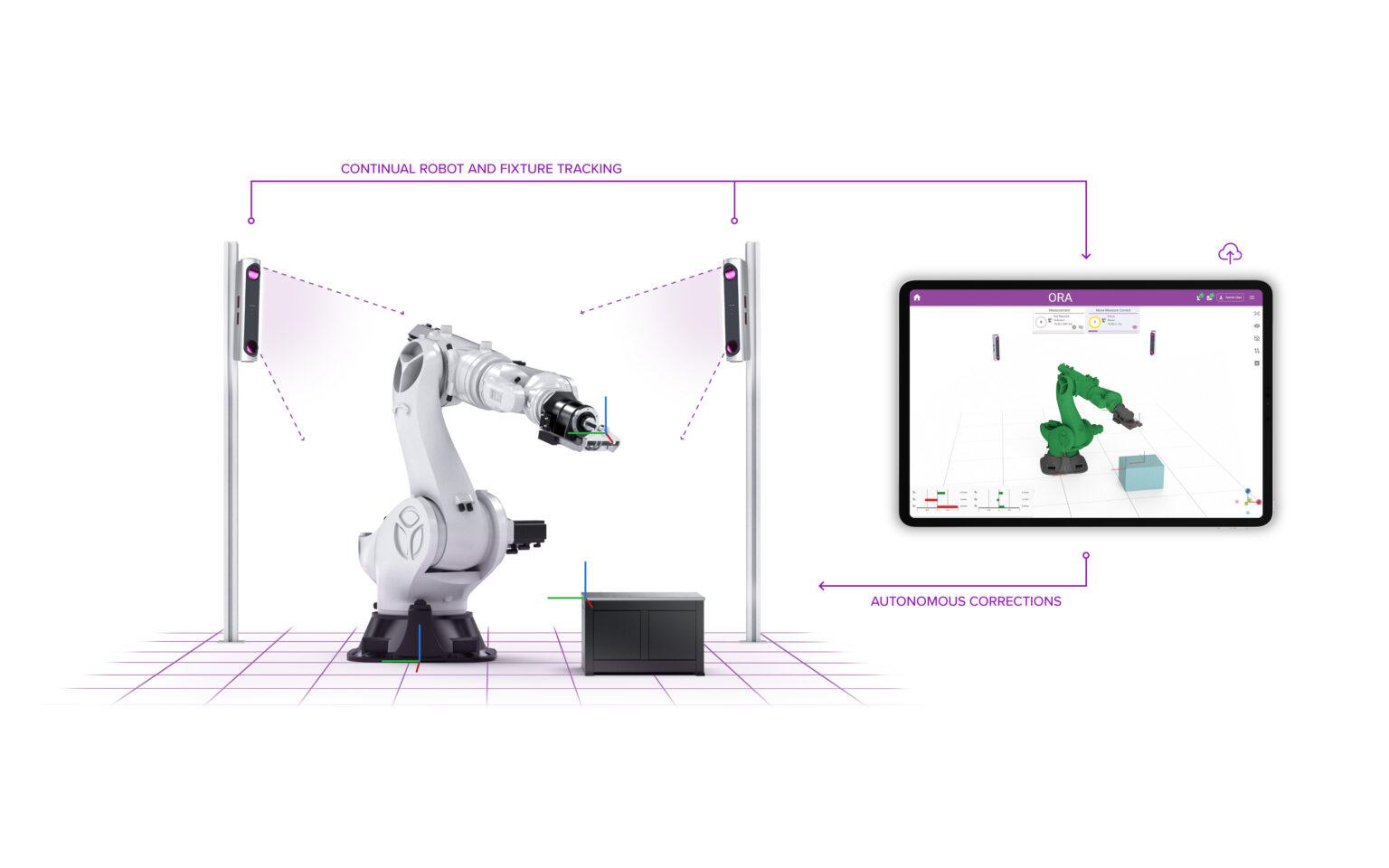

ORA provides global coordinate frame management, allowing frame visualisation from multiple sensors, robots, fixtures and other key datums.

The software platform analyses the data from the sensor network. This can be autonomously fed back in-process to the robot controller to correct for any variation

Integrating seamlessly with the broader smart factory architecture, ORA can communicate directly with the robot controller or PLC via an API as well as being able to send data directly to the MES platform at the factory level. This enables ORA to operate as a ‘black-box’ providing data autonomously on demand.

Applications

ORA robot control software benefits a wide range of applications from robot based machining through to assembly operations. The common theme is that manufacturers are looking to improve the accuracy, flexibility or autonomous nature of their automated process.

3 Steps to improving Robot Accuracy by measuring, teaching and monitoring process performance

This technical paper tackles a range of assumptions associated with robots: repeatability vs accuracy, the interplay between robot payload and stiffness, as well as flexibility vs in-process adaptability.

Get in touch to discover how ORA can control your Smart Factory

From a technical demo to a consultancy discussion we can help you identify the best solution for your automated processes.